Safe and Simple: How Torque Wrenches Improve DIY Car Repairs

The Hidden Cost of Overtightening

Everyday drivers often underestimate the risks of overtightening. A wheel bolt forced too far can warp a brake rotor, and a spark plug with extra pressure may crack its housing. These are not minor mistakes—they can cost hundreds of dollars in replacement parts. What feels like “extra security” is actually structural damage in disguise. For DIYers, the difference between a reliable fix and an expensive repair often comes down to tool choice. That is where a Torque Wrench becomes indispensable.

Why DIY Repairs Need Torque Control

Unlike professional workshops, home garages rarely have standardized procedures. Many DIYers tighten bolts by feel or use impact guns without torque feedback. This creates three recurring problems:

-

Threads weaken long before visible failure.

-

Parts such as aluminum cylinder heads are prone to cracking.

-

Vehicle safety is compromised—brakes, wheels, and suspension can suffer hidden damage.

A Mechanical Torque Wrench or Digital Torque Wrench eliminates guesswork. By delivering precise, measurable force, it transforms casual tightening into professional-level accuracy.

Comparing Torque Wrench Options

Choosing the right tool depends on how often and how precisely you work:

| Tool Type | Best Use Cases | Key Advantages |

|---|---|---|

| Mechanical Torque Wrench | Wheel nuts, suspension, heavy fasteners | Affordable, durable, tactile click feel |

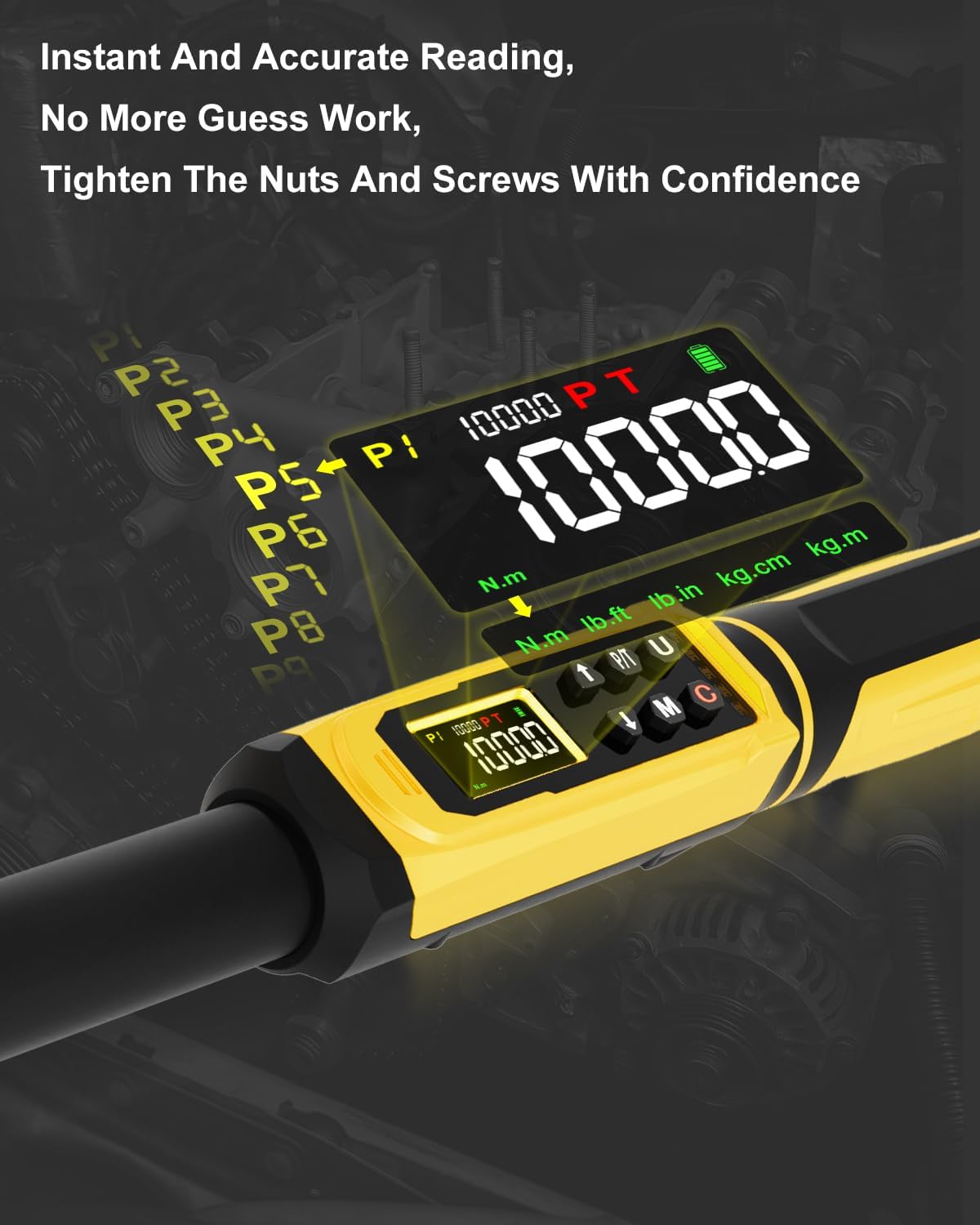

| Digital Torque Wrench | Spark plugs, engine assemblies | ±2% accuracy, LCD display, memory save |

| Digital Torque Adapter | Occasional DIY jobs, multi-tool use | Compact, converts ratchets into torque tools |

This variety ensures every DIY mechanic can find a tool that balances cost and precision.

Torque-Sensitive Repairs That Matter Most

Some DIY tasks demand accuracy more than others. Consider these examples where torque wrenches protect both safety and investment:

-

Wheel Lug Nuts: Over-tightening can warp rotors, while under-tightening risks loose wheels. Recommended range: 80–100 ft-lb.

-

Spark Plugs: Only 15–20 ft-lb needed. Aluminum heads strip easily if forced.

-

Brake Calipers: Should be tightened around 25–35 ft-lb. Too much torque cracks brackets.

-

Oil Drain Plugs: Typically 20–30 ft-lb. Over-tightening leads to leaks and damaged pans.

By respecting these values, DIY repairs not only become safer but also extend the lifespan of vehicle parts.

Torque Tips Every DIY Mechanic Should Know

Getting results like a professional mechanic requires both tools and habits. These tips help maximize accuracy:

-

Tighten in a pattern: For wheels, use a crisscross sequence to distribute pressure evenly.

-

Preload the tool: On click-type wrenches, apply 2–3 test pulls to stabilize internal springs.

-

Mind the accessories: Long extensions can distort torque readings—shorter is safer.

-

Protect spark plug threads: Apply anti-seize to reduce galling and ensure consistent torque.

-

Trust the tool, not your instinct: Stop at the first click or beep; adding “a little more” ruins accuracy.

Adopting these practices ensures your Best Torque Wrench performs at its peak, bringing workshop precision into your home garage.

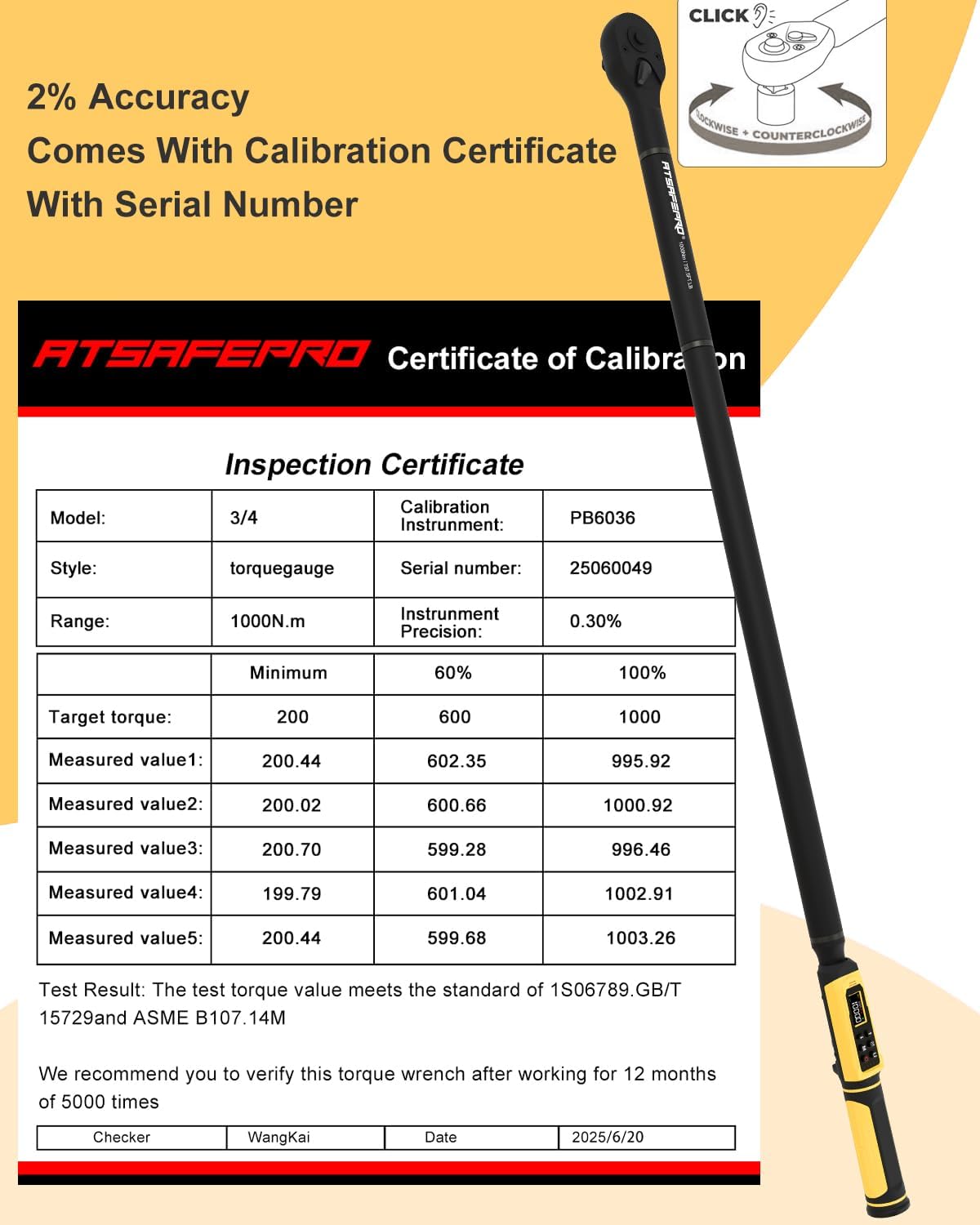

Why ATSAFEPRO Delivers More for DIY Users

ATSAFEPRO torque wrenches are designed for users who want safety without complexity:

-

Factory-calibrated to ISO 6789 standards.

-

Dual scales (Nm and ft-lb) for flexible use.

-

Chrome-vanadium steel build for durability.

-

Ergonomic handles that reduce fatigue during longer tasks.

These details make the difference between a tool that simply works and a tool that protects your car over years of service.

Safe Repairs Begin with the Right Tools

Overtightening is a silent hazard in DIY auto repair, but it is entirely preventable. By choosing the right torque wrench—be it mechanical, digital, or adapter—you gain control, accuracy, and peace of mind.

ATSAFEPRO provides torque solutions tailored for home mechanics who want professional-grade safety. Explore our full product range on the homepage or connect with us directly via the contact page.