Avoid Overtightening: How the Best Torque Wrench Protects Your Vehicle Parts

Why Overtightening Is More Than a Minor Mistake

Most drivers think of overtightening as harmless, but engineering data tells a different story. Studies by the Society of Automotive Engineers (SAE) show that over 30% of post-maintenance component failures stem from improper torque application. When bolts are stretched beyond their yield point, their clamping force actually drops, leaving assemblies weaker than before. For example:

-

Lug nuts overtightened by 30% can permanently deform brake rotors, causing vibration.

-

Cylinder head bolts exceeding specification may crush gaskets, leading to coolant leaks and engine failure.

This is why the Best Torque Wrench is not about convenience—it is about ensuring bolts hold their load without crossing material stress limits.

Different Types of Torque Wrenches and Their Roles

To truly prevent overtightening, it is not enough to “tighten carefully.” The right torque tool makes the difference. ATSAFEPRO provides a range of solutions that directly address different fastening needs:

-

Torque Wrench (General Use)

A classic adjustable tool, suitable for most day-to-day maintenance. It helps drivers apply consistent force when installing wheels or performing basic repairs. -

Mechanical Torque Wrench

Designed for durability, this type is widely used in suspension and wheel service. The click or beam feedback tells the user exactly when the target torque has been reached, reducing the risk of overstretching bolts. -

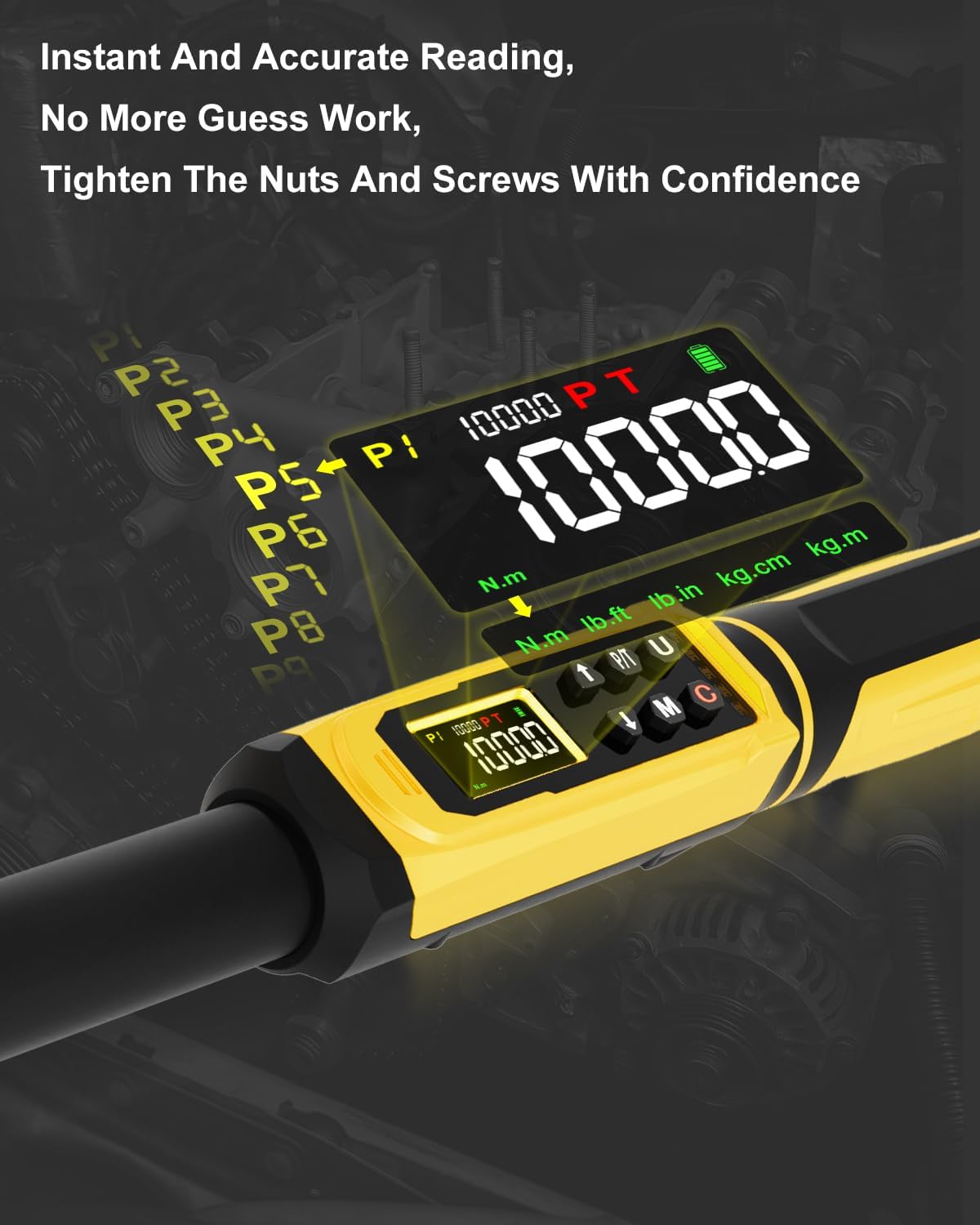

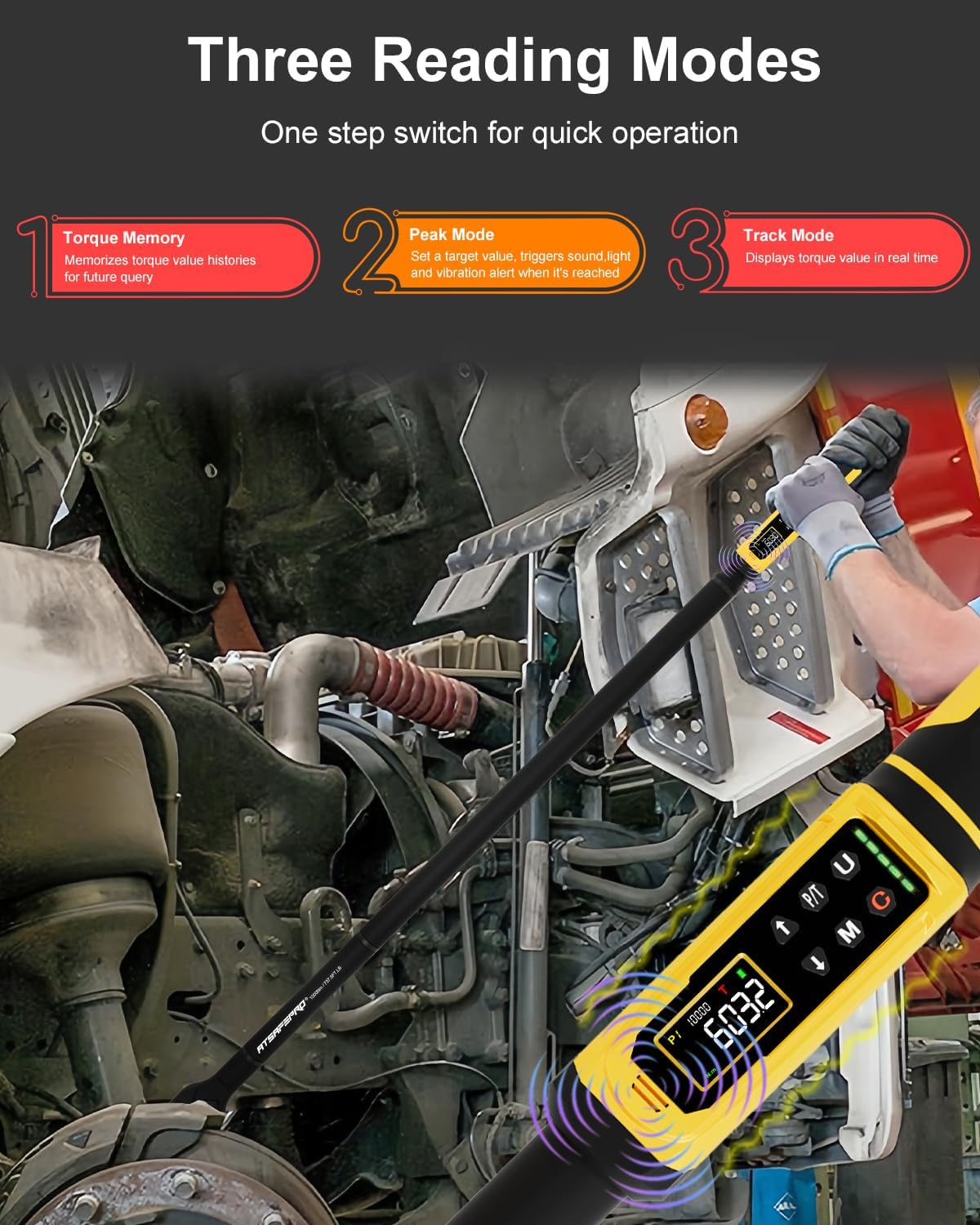

Digital Torque Wrench

Built for high-precision tasks, such as engine assembly. With ±2% accuracy, digital readouts, and memory functions, it gives professionals confidence when working with sensitive components where a few ft-lb of overtightening could cause costly failures. -

Digital Torque Adapter

A portable solution for technicians on the go. It transforms a standard ratchet into a calibrated torque tool, ensuring accuracy even outside the workshop.

Each type is designed not as a generic tool, but as a safeguard against overtightening in specific scenarios—from tightening lug nuts on highways to assembling engine parts in precision repair shops.

Real Torque Values That Matter

Talking about “accuracy” is abstract—real numbers tell the story. Below are typical torque specifications (based on manufacturer guidelines) where precision is critical:

| Component | Typical Torque Range | Why Precision Matters |

|---|---|---|

| Wheel Lug Nuts (sedan) | 80–100 ft-lb | Too tight: warped rotors; too loose: wheel detachment |

| Cylinder Head Bolts | 65–75 ft-lb (with sequence) | Prevents gasket leaks and engine block warping |

| Brake Caliper Bolts | 25–35 ft-lb | Protects aluminum brackets from cracking |

| Spark Plugs | 15–20 ft-lb | Prevents thread stripping in cylinder heads |

| Bicycle Stem Bolts | 5–6 Nm | Protects lightweight carbon fiber from crushing |

These examples show that torque accuracy is not theoretical—it’s practical, measurable, and essential.

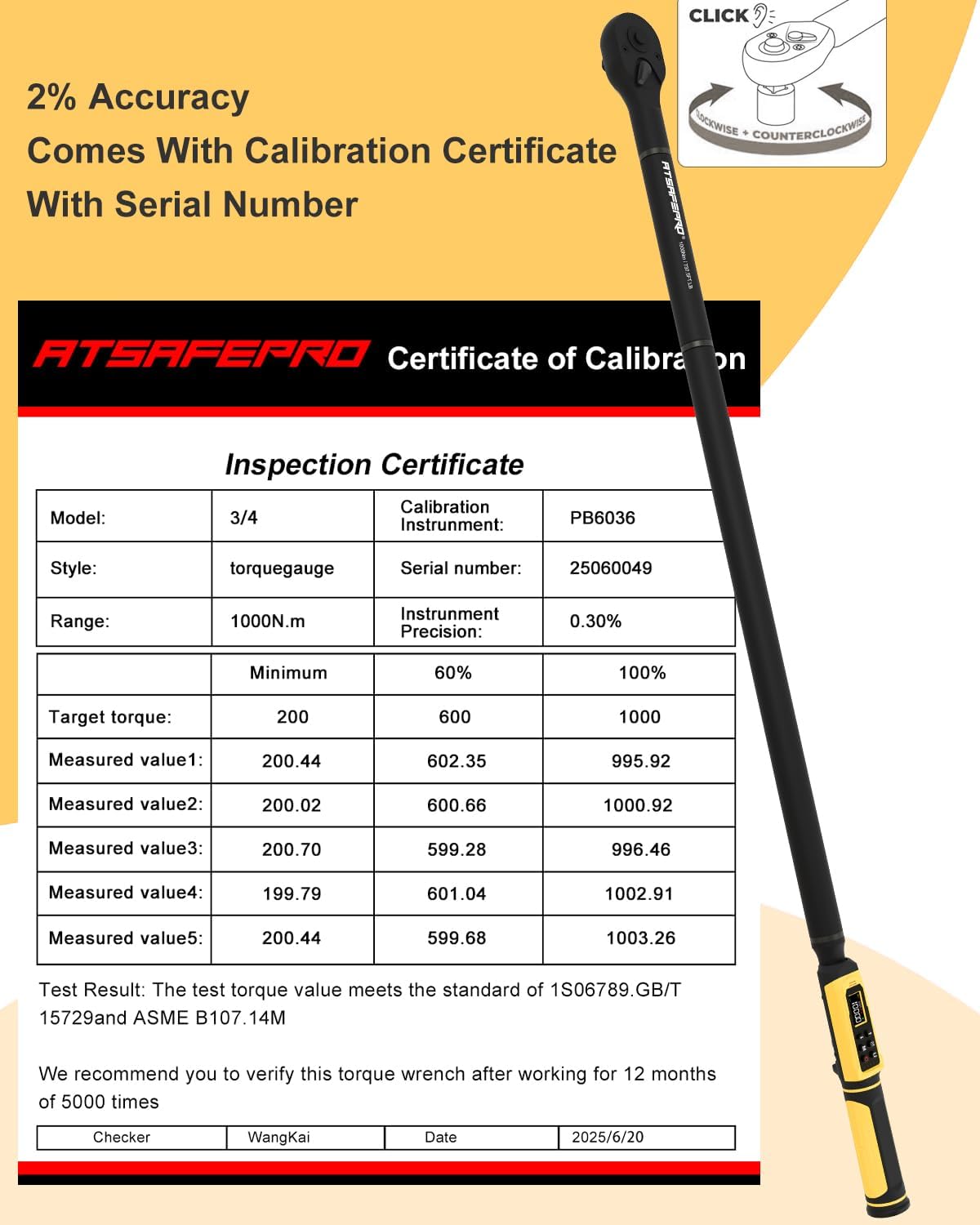

Why Calibration and Maintenance Define Accuracy

Even the best tools drift over time. Mechanical springs lose tension; digital sensors shift with temperature and wear. Calibration is the backbone of reliability:

-

Frequency: Every 12 months, or after 5,000 cycles.

-

Method: Calibration compares applied torque against a certified reference device.

-

Signs of Drift: Inconsistent clicks, loose fasteners despite tightening, or readings off by more than 3%.

Practical advice: keep a calibration log for workshop tools. Professional shops that cannot prove torque tool calibration may even face liability issues if improper tightening leads to accidents.

Balancing Tool Types: Which to Choose?

Different users will find different torque solutions better suited to their workflow.

| User Type | Recommended Tool | Why It Fits |

|---|---|---|

| DIY Car Owner | Mechanical Torque Wrench | Affordable, rugged, and reliable for general tasks |

| Professional Workshop | Digital Torque Wrench | Provides memory storage, backlit displays, ±2% accuracy |

| Mobile Technician | Digital Torque Adapter | Portable and versatile; adds precision without heavy investment |

| Fleet Operator | Both Mechanical + Digital | Combines durability for routine jobs with digital accuracy for critical components |

The right choice depends not only on budget but also on the frequency and criticality of torque applications.

ATSAFEPRO’s Commitment to Precision

ATSAFEPRO builds more than tools; it builds confidence. Every torque product undergoes 100% factory testing, with ISO-certified processes ensuring consistent results. Mechanical models deliver tactile reliability, digital versions integrate advanced electronics, and adapters offer unmatched portability. Together, they provide a system of torque solutions that meet the needs of modern maintenance.

This approach is why ATSAFEPRO is trusted by individual drivers, professional garages, and global distributors alike. It’s not about one tool—it’s about building a complete toolkit for accuracy and safety.

A Precision Investment That Protects More Than Bolts

The hidden cost of overtightening is measured not only in broken bolts but in safety risks, downtime, and reputation. For professionals, it can mean customer trust. For fleet operators, it can mean fewer roadside breakdowns. For drivers, it means peace of mind.

Choosing the Best Torque Wrench is ultimately about choosing protection—of your vehicle, your investment, and your safety. ATSAFEPRO delivers that protection across Mechanical Torque Wrenches, Digital Torque Wrenches, and Digital Torque Adapters, creating tools that are as reliable as the vehicles they service.

To explore our full range, visit our homepage or get tailored advice by visiting our contact page.