Understanding Torque Wrenches: The Foundation of Precision Work

When it comes to precision tools in mechanical and automotive tasks, the ATsafepro Torque wrench stands out as a game-changer for professionals and DIYers alike. This innovative tool combines advanced features with user-friendly design, ensuring accurate torque application every time. In this article, we'll explore the differences between the ATsafepro Torque wrench and traditional options like the Digital Torque wrench and Mechanical Torque wrench, highlighting their strengths and weaknesses through a detailed comparison.

Torque wrenches are essential for applying the correct amount of force to fasteners, preventing over-tightening or under-tightening that could lead to failures. The ATsafepro Torque wrench, with its multifunctional capabilities, addresses these needs head-on. Unlike basic models, it integrates modern technology for enhanced precision, making it ideal for a range of applications from engine repairs to assembly lines.

Digital Torque Wrench vs. ATsafepro Torque Wrench: Technology and Accuracy

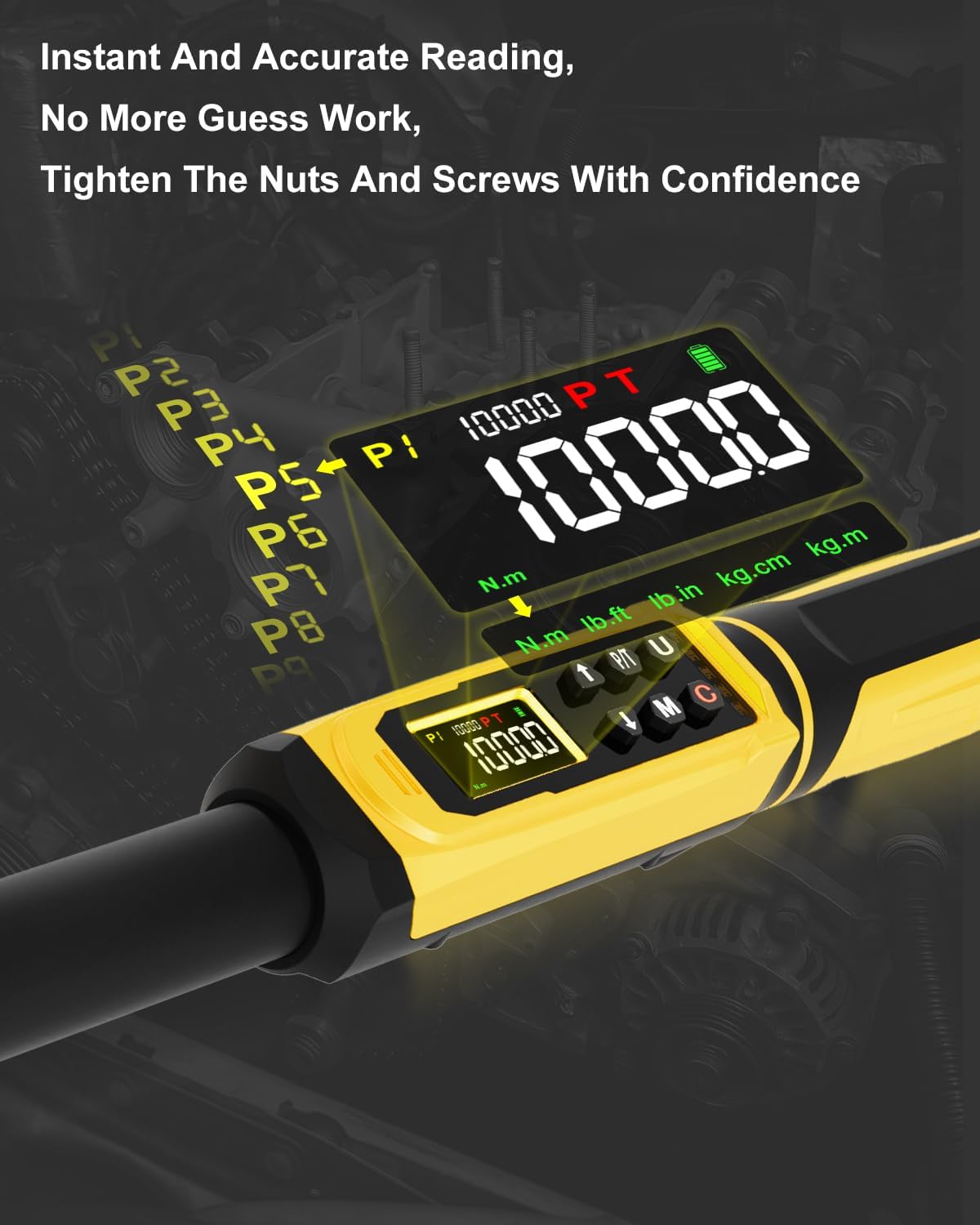

The Digital Torque wrench represents a significant leap from older analog tools, offering real-time feedback through an LCD screen that displays torque values as you work. This allows users to monitor progress instantly, reducing errors in high-stakes environments like aviation or heavy machinery maintenance. However, while the Digital Torque wrench excels in readability, it often relies on batteries, which can fail unexpectedly during critical tasks, leading to downtime.

In contrast, the ATsafepro Torque wrench builds on this digital foundation but enhances it with superior ergonomics and durability. Featuring an easy-to-read LCD display similar to the Digital Torque wrench, the ATsafepro Torque wrench ensures accuracy across various applications, from automotive bolt tightening to industrial fastening. What sets it apart is its adjustable settings, which provide finer control than many standard Digital Torque wrenches. For instance, the ATsafepro model allows for quick calibration and multiple torque presets, making it more versatile for users switching between tasks. While a typical Digital Torque wrench might offer basic peak hold functions, the ATsafepro Torque wrench includes advanced alerts—both audible and visual—that prevent over-torquing, a common issue with digital models that lack such reinforcements.

Moreover, battery life is a key differentiator. The ATsafepro Torque wrench is designed with energy-efficient components, extending usage periods compared to many Digital Torque wrenches that drain power quickly under heavy use. This reliability makes the ATsafepro a preferable choice for professionals who can't afford interruptions. On the flip side, Digital Torque wrenches are often lighter and more compact, which might appeal to those prioritizing portability over extended features. Yet, when precision and long-term performance matter, the ATsafepro Torque wrench's robust build—complete with a durable carrying case—outshines its counterparts, ensuring it's ready for transport without compromising on toughness.

Mechanical Torque Wrench vs. ATsafepro Torque Wrench: Simplicity Meets Innovation

The Mechanical Torque wrench has long been the go-to for its straightforward, no-frills operation. It uses a simple click mechanism to signal when the desired torque is reached, relying on mechanical scales for measurement. This design is praised for its robustness; without electronics, a Mechanical Torque wrench is immune to battery failures or digital glitches, making it a reliable option in harsh environments like construction sites or outdoor repairs.

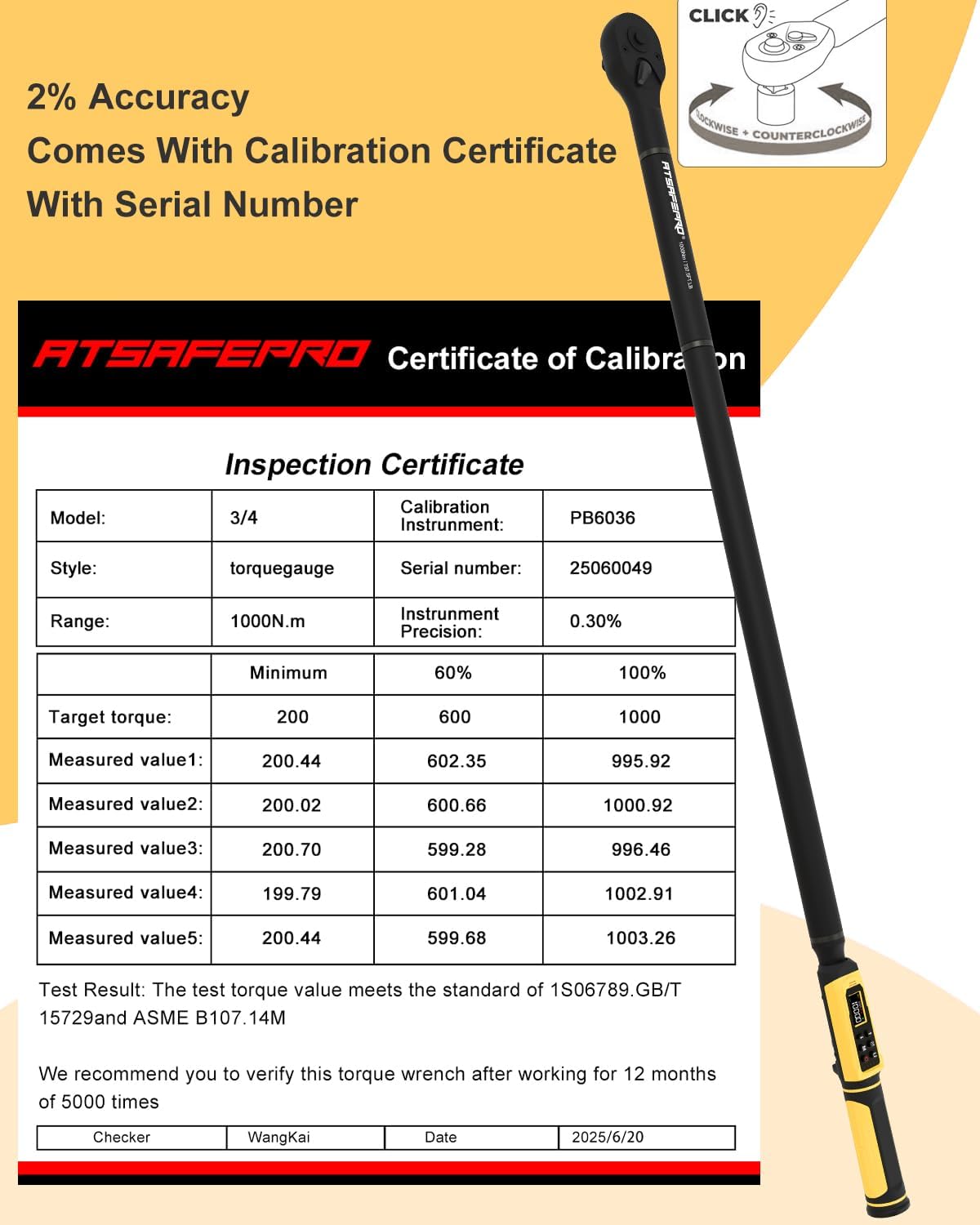

However, the Mechanical Torque wrench falls short in precision and ease of use compared to the ATsafepro Torque wrench. Reading analog dials on a Mechanical Torque wrench can be challenging in low-light conditions or for fine adjustments, often leading to inaccuracies of up to 4-6% in some models. The ATsafepro Torque wrench, on the other hand, leverages digital precision to achieve accuracy within 2%, providing clear, illuminated readings that eliminate guesswork. This contrast is particularly evident in tasks requiring exact specifications, such as bicycle assembly or engine tuning, where the Mechanical Torque wrench's subjectivity can introduce errors.

Ergonomics also play a pivotal role in this comparison. Mechanical Torque wrenches typically feature basic handles that may cause fatigue during prolonged use, whereas the ATsafepro Torque wrench's ergonomic design distributes weight evenly, reducing strain on the wrist and hand. Imagine working on a full-day automotive project: the Mechanical Torque wrench might feel cumbersome after hours, while the ATsafepro's comfortable grip and lightweight construction keep you productive. Additionally, the ATsafepro Torque wrench's multifunctional nature allows for both foot-pound and Newton-meter measurements seamlessly, a flexibility not always present in rigid Mechanical Torque wrenches that require separate models for different units.

Durability is another area of contrast. While Mechanical Torque wrenches are built like tanks, they can suffer from wear in the internal spring mechanisms over time, leading to calibration drift. The ATsafepro Torque wrench counters this with high-quality materials and easy maintenance features, ensuring longevity without frequent recalibrations. For DIY enthusiasts or mechanics, this means fewer headaches and more consistent results. Although Mechanical Torque wrenches are generally cheaper upfront, the long-term value of the ATsafepro Torque wrench—backed by its comprehensive carrying case and warranty—makes it a smarter investment for serious users.

Choosing the Right Tool: When to Opt for ATsafepro Over Others

In comparing these tools, the ATsafepro Torque wrench emerges as the superior choice for those seeking a balance of precision, usability, and reliability. While the Digital Torque wrench offers modern conveniences, it can be hindered by power dependencies, and the Mechanical Torque wrench provides timeless simplicity but lacks the finesse for complex jobs. The ATsafepro Torque wrench integrates the best of both worlds: digital accuracy with mechanical durability, all wrapped in an ergonomic package that's perfect for extended use.

Consider a scenario in an auto shop: a mechanic using a Mechanical Torque wrench might overshoot torque on a cylinder head bolt due to a misread scale, risking engine damage. Switching to the ATsafepro Torque wrench, the clear LCD and alerts ensure perfect application every time. Similarly, compared to a Digital Torque wrench, the ATsafepro's enhanced battery management and preset options streamline workflows, saving time and reducing errors.

For industrial applications, the ATsafepro Torque wrench's versatility shines. It handles diverse torque ranges—from 10 to 150 foot-pounds—more adeptly than many Mechanical Torque wrenches limited to specific scales. Professionals appreciate its confidence-inspiring performance, whether tightening lug nuts or assembling machinery components. Even for home users, the included carrying case makes storage effortless, contrasting with bulkier Mechanical Torque wrenches that gather dust in garages.

Ultimately, the choice boils down to your needs. If you value unyielding simplicity, a Mechanical Torque wrench suffices for basic tasks. For tech-savvy precision without frills, the Digital Torque wrench works well. But for comprehensive excellence that adapts to any challenge, the ATsafepro Torque wrench is unmatched. Its design fosters confidence, ensuring tasks are completed accurately and efficiently, making it an indispensable tool in any toolkit.

Real-World Applications and Final Thoughts

In real-world scenarios, the ATsafepro Torque wrench's advantages become crystal clear. Automotive enthusiasts tightening suspension components find its digital feedback far superior to the Mechanical Torque wrench's click system, which can be misleading under vibration. Industrial workers benefit from its adjustable settings, outpacing the one-size-fits-most approach of many Digital Torque wrenches.

This tool's reliability extends to DIY projects, like furniture assembly or bike repairs, where precision prevents stripping threads—issues common with less accurate Mechanical Torque wrenches. The ATsafepro Torque wrench's ergonomic handle also minimizes user error from fatigue, a subtle but significant edge over clunkier digital alternatives.

In conclusion, while each type has its place, the ATsafepro Torque wrench offers the most well-rounded solution. By contrasting its features against Digital and Mechanical Torque wrenches, it's evident that this tool delivers precision, comfort, and durability in one package. Whether you're a pro or hobbyist, investing in the ATsafepro Torque wrench elevates your work, ensuring every twist is just right. With over 800 words of insight, this comparison underscores why it's the top pick for torque mastery.