Discovering the Precision of the ATsafepro Torque Wrench

In the world of mechanical work and automotive repairs, having the right tools can make all the difference in achieving accurate and reliable results. The ATsafepro Torque wrench stands out as a premium choice for professionals and DIY enthusiasts alike, offering unmatched precision in applying the correct amount of torque to fasteners. This innovative tool ensures that bolts and nuts are tightened to exact specifications, preventing over-tightening that could damage components or under-tightening that might lead to failures. Whether you're working on engines, machinery, or home projects, the ATsafepro Torque wrench combines durability with user-friendly features to enhance your efficiency.

Exploring Digital Torque Wrench Technology

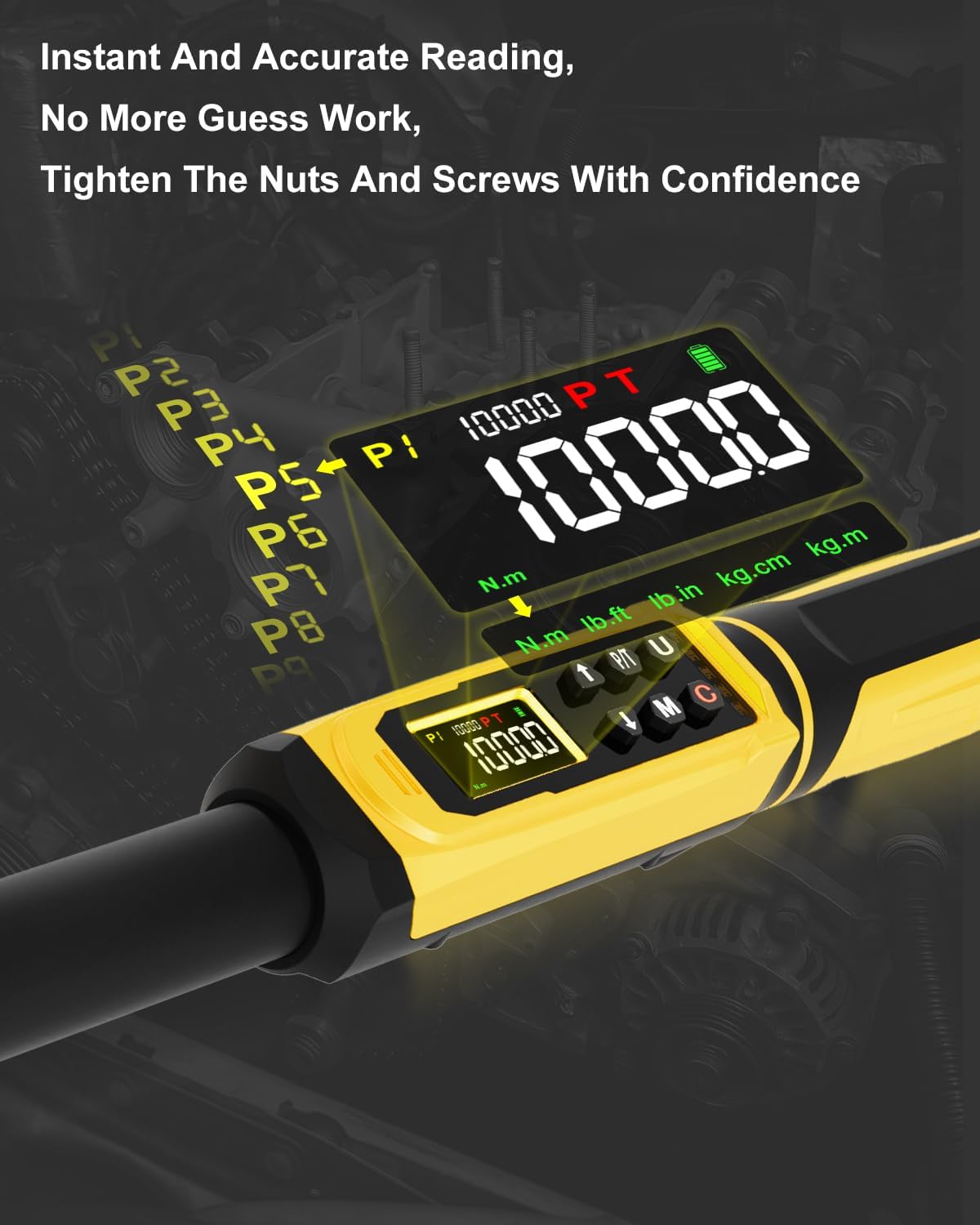

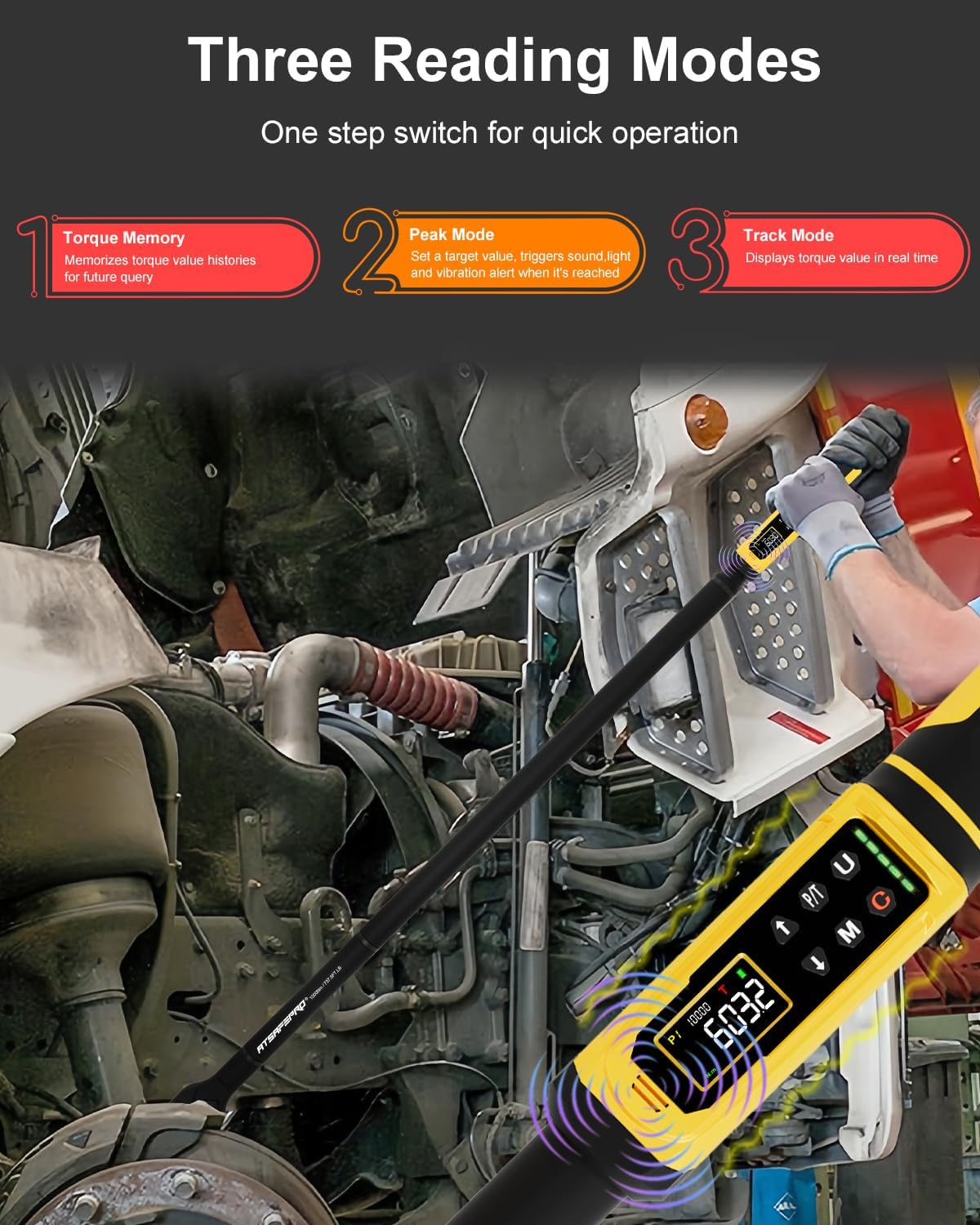

One of the fascinating aspects of modern tools is the integration of digital features, and the digital torque wrench variant within the ATsafepro lineup exemplifies this advancement. Unlike traditional models, a digital torque wrench provides real-time readings on an easy-to-read display, allowing users to monitor torque application precisely as they work. This technology minimizes human error, which is crucial in high-stakes environments like aviation or automotive assembly. The ATsafepro digital torque wrench, for instance, can alert users with audible and visual signals when the desired torque level is reached, making it an indispensable tool for tasks requiring exact measurements. Its battery-powered operation ensures portability without sacrificing accuracy, and the data logging capability allows for record-keeping of torque values for quality assurance purposes.

The Reliability of the Mechanical Torque Wrench

For those who prefer a more straightforward approach, the mechanical torque wrench remains a timeless option, and ATsafepro delivers excellence in this category as well. A mechanical torque wrench operates using a simple yet effective mechanism, typically involving a spring and scale that visually indicates torque levels as you turn the handle. This design is robust and doesn't rely on electronics, making it ideal for rugged job sites where dust, moisture, or extreme temperatures might interfere with digital components. The ATsafepro mechanical torque wrench is calibrated for consistent performance, with a clear micrometer-style adjustment that locks securely to prevent accidental changes during use. Its construction from high-strength materials ensures it withstands heavy use over time, providing value for money in professional workshops.

Unpacking the ATSAFEPRO Red Torque Wrench Set

At the heart of the ATsafepro Torque wrench offerings is the ATSAFEPRO Red Torque Wrench Set, a comprehensive kit designed to cover a wide array of applications. This set includes three specialized wrenches, each with distinct drive sizes and torque ranges tailored to different tasks. The 1/2-inch drive wrench, measuring 41 cm in length, handles torque from 10 to 170 FT.LB, making it perfect for heavy-duty jobs like suspending engines or securing large structural bolts. Its ergonomic grip reduces hand fatigue during prolonged use, while the vibrant red finish not only enhances visibility but also resists corrosion for extended durability.

The 3/8-inch drive model, at 30 cm long, offers a versatile range of 5 to 50 FT.LB, suitable for everyday automotive repairs such as brake work or suspension adjustments. This wrench's adjustable scale allows for fine-tuning to manufacturer specifications, ensuring components like cylinder heads are fastened without risk of warping. Complementing these is the compact 1/4-inch drive wrench, 24 cm in length, which precisely manages 20 to 240 IN.LB for delicate operations in tight spaces, such as electronics assembly or bicycle maintenance.

Enhancing Versatility with Drive Head Adapters

What truly sets the ATSAFEPRO Red Torque Wrench Set apart is the inclusion of drive head adapters, which expand its utility across various socket sizes. The set features a 1/2 to 3/8 drive head adapter for adapting larger wrenches to medium sockets, a 3/8 to 1/2 drive head for the reverse, and a 1/4 to 3/8 drive head for fine work with slightly larger fittings. These adapters are crafted from hardened steel to maintain torque integrity, preventing slippage or breakage under load. By incorporating these, the ATsafepro Torque wrench set transforms into a multi-purpose toolkit, reducing the need for multiple individual purchases and streamlining workflows in garages or fabrication shops.

Comparing Digital and Mechanical Options in the ATsafepro Lineup

When choosing between a digital torque wrench and a mechanical torque wrench, the ATsafepro range caters to both preferences with seamless integration. The digital models shine in precision-driven scenarios where immediate feedback is essential, such as in quality control labs, where even a slight deviation can compromise safety. Conversely, the mechanical torque wrench excels in fieldwork, offering simplicity and reliability without the worry of battery life or electronic failures. Both types in the ATsafepro collection feature a locking mechanism to secure torque settings, ensuring consistency across uses. This duality allows users to select based on the job's demands, whether it's the high-tech precision of digital readings or the no-fuss operation of mechanical gauges.

Practical Applications and Benefits

In practical terms, the ATsafepro Torque wrench finds its place in numerous industries beyond just automotive repair. Mechanics use it for wheel installations to prevent lug nut failures, while aerospace technicians rely on its accuracy for assembling critical components. Home users benefit from its ease in furniture assembly or bike repairs, avoiding stripped screws that could ruin projects. The tool's design emphasizes safety, as proper torque application reduces vibration-induced loosening and extends the lifespan of fastened parts. Moreover, the red color coding aids in quick identification within busy toolboxes, promoting organized and efficient work habits.

Maintenance Tips for Longevity

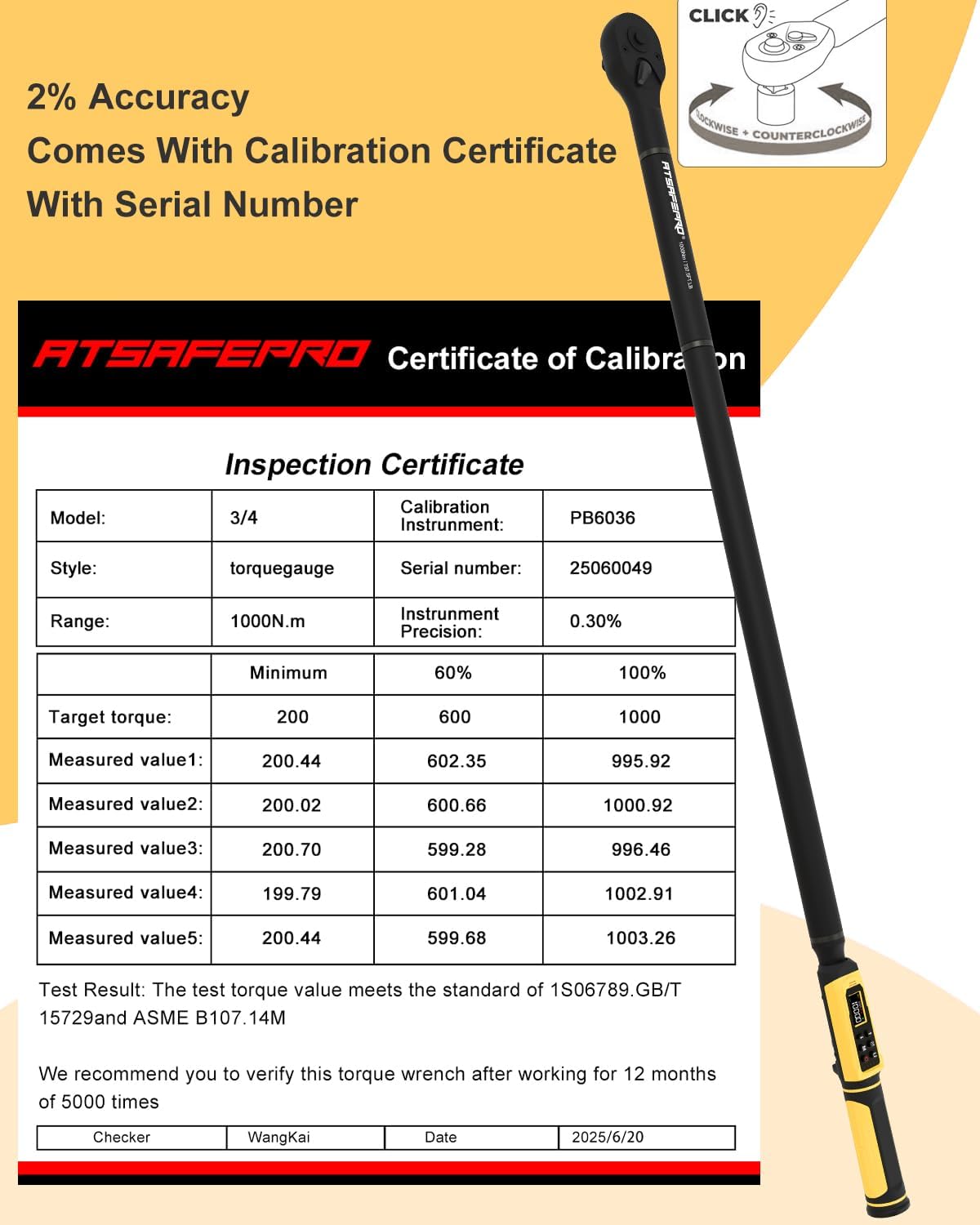

To maximize the lifespan of your ATsafepro Torque wrench, regular maintenance is key. For mechanical versions, periodically check the calibration by testing against known standards, and store it in a dry environment to prevent rust on the scales. Digital models require battery replacements and occasional firmware updates for optimal performance. Cleaning after each use removes debris that could affect accuracy, and avoiding drops preserves the internal mechanisms. With proper care, these tools can serve for years, proving to be a wise investment for any serious toolkit.

Why Choose ATsafepro for Your Torque Needs

Ultimately, the ATsafepro Torque wrench represents a blend of innovation, reliability, and practicality that elevates any mechanical endeavor. Whether opting for the digital torque wrench's advanced features or the mechanical torque wrench's sturdy simplicity, users gain tools that deliver professional-grade results. The ATSAFEPRO Red Torque Wrench Set, with its comprehensive inclusions, ensures you're equipped for virtually any fastening challenge. Investing in ATsafepro means embracing precision that safeguards your projects and enhances your craftsmanship, making it a go-to choice for discerning professionals worldwide.