Introduction to the ATsafepro Torque Wrench: A Game-Changer in Precision Tools

In the world of fasteners and assembly, the ATsafepro Torque wrench stands out as a versatile and reliable instrument for applying exact torque levels. This multifunctional tool is engineered for both professional mechanics and DIY hobbyists who demand accuracy without compromise. Featuring a digital display that provides real-time torque readings, the ATsafepro Torque wrench ensures that every fastener is tightened to perfection, reducing the risk of over- or under-tightening. As we delve into its capabilities, we'll compare it against traditional options like the Digital Torque wrench and Mechanical Torque wrench to highlight why it might be the superior choice for modern applications.

Design and Ergonomics: ATsafepro vs. Digital and Mechanical Variants

The ATsafepro Torque wrench boasts an ergonomic handle that molds comfortably to the user's hand, promoting a secure grip even during prolonged use. This design minimizes fatigue, which is a common complaint with bulkier Mechanical Torque wrenches that often feature rigid, less contoured grips. In contrast, while a Digital Torque wrench shares the sleek profile of the ATsafepro, its electronic components can sometimes add unnecessary weight, making it less ideal for extended sessions. The ATsafepro strikes a balance, integrating advanced digital features without sacrificing portability or comfort. Its inclusion of a sturdy carrying case further enhances its practicality, allowing seamless transport to job sites—something not always standard with basic Mechanical Torque wrenches that lack protective accessories.

When comparing durability, the ATsafepro Torque wrench's robust construction holds up well against the wear and tear of daily professional use. Mechanical Torque wrenches, though simple and rugged, can suffer from internal spring degradation over time, leading to inconsistent readings. Digital Torque wrenches, on the other hand, rely on batteries and sensitive electronics that might falter in harsh environments like automotive garages or construction sites. The ATsafepro addresses these concerns with its reliable digital interface backed by an included Allen key for easy calibration, ensuring longevity and precision that outpaces both counterparts in demanding scenarios.

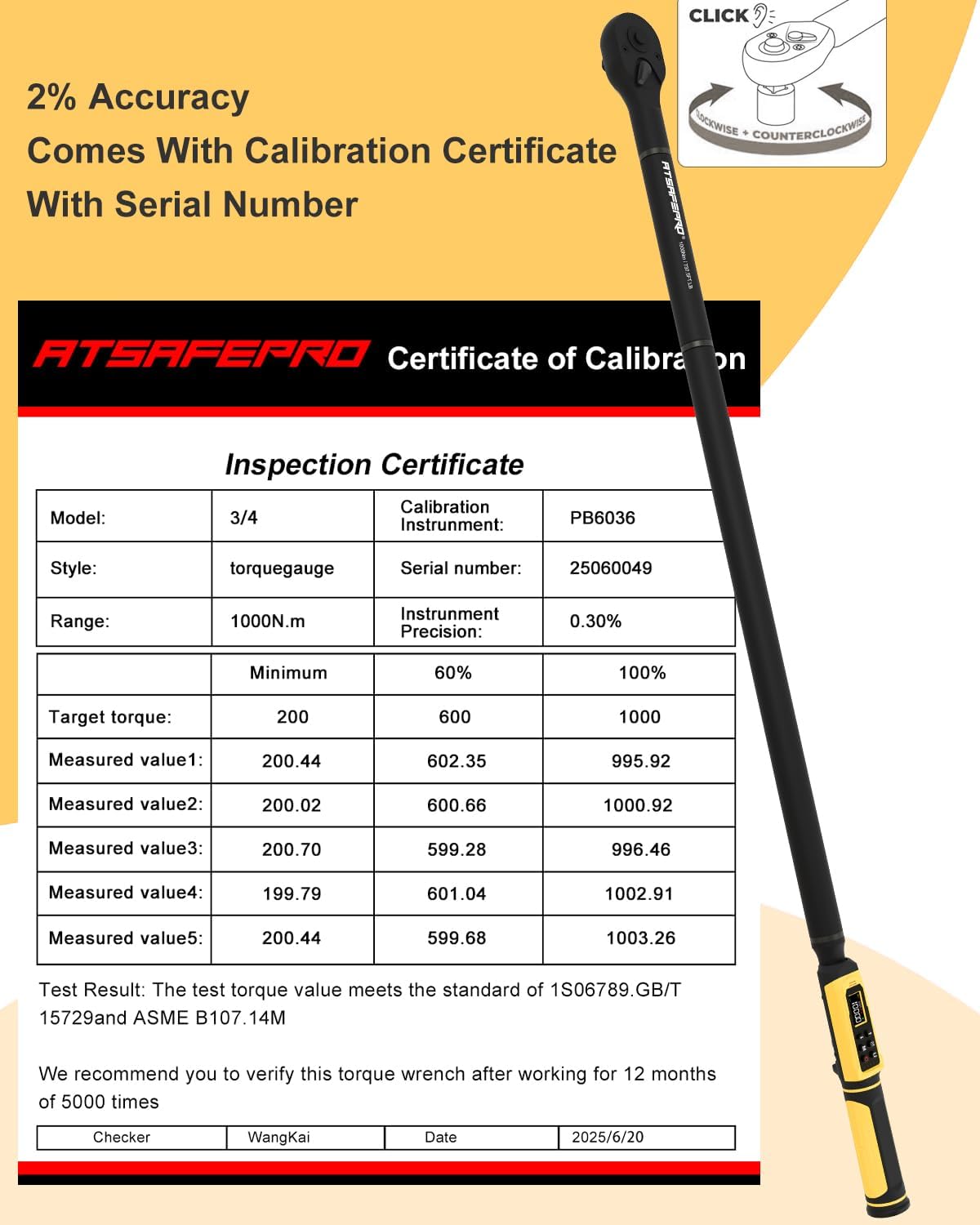

Precision and Technology: How the ATsafepro Outshines Competitors

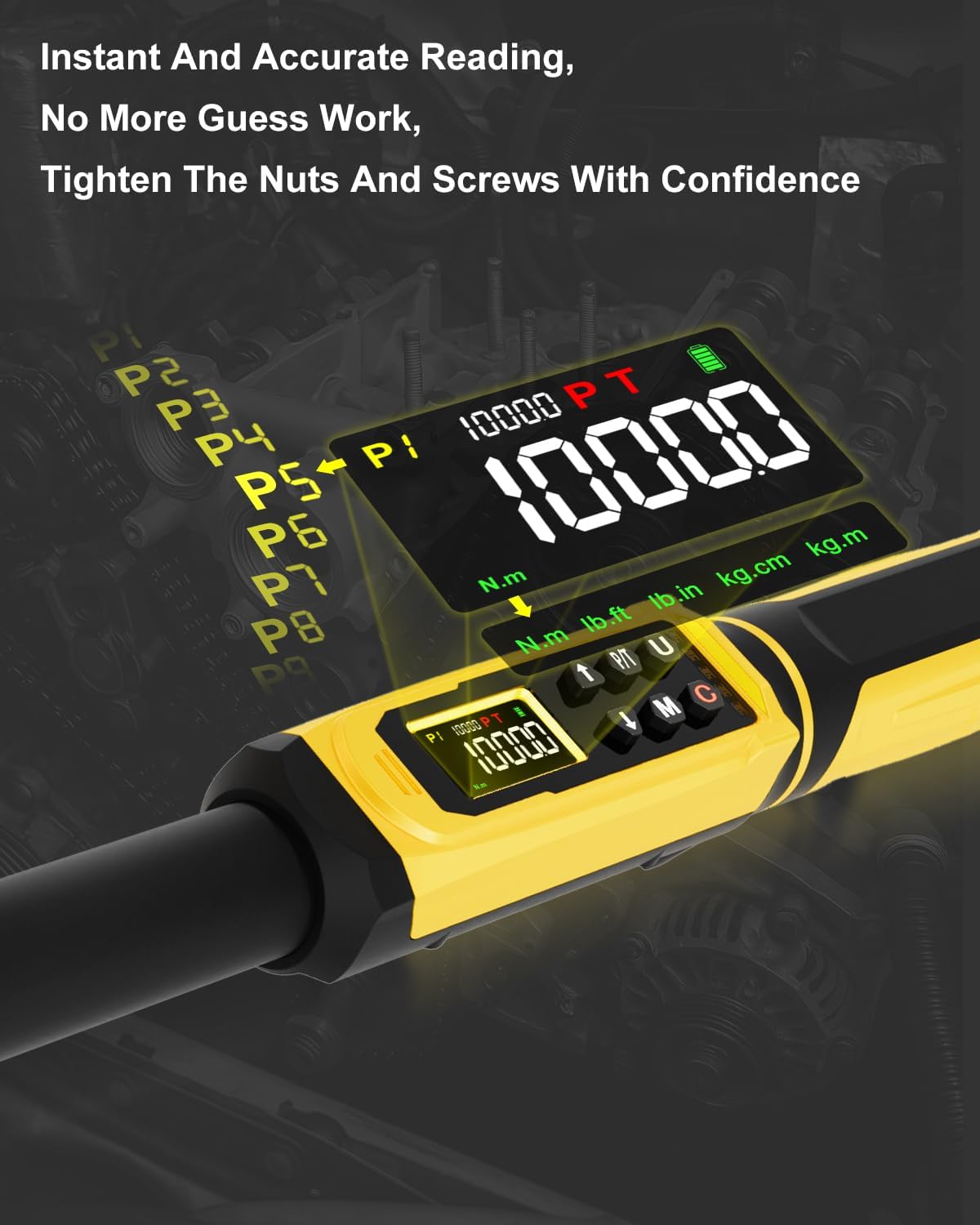

Precision is the hallmark of any quality torque tool, and here the ATsafepro Torque wrench excels with its clear digital display that shows torque values in real-time, often down to the decimal point. This level of accuracy is a step above what most Mechanical Torque wrenches offer, which typically rely on analog scales or click mechanisms that require user interpretation and can introduce human error. For instance, a Mechanical Torque wrench might 'click' to signal the target torque, but factors like hand fatigue or environmental noise can make this feedback unreliable. In comparison, a Digital Torque wrench provides similar numerical feedback to the ATsafepro, but the latter's multifunctional design includes preset modes for various torque units (like Nm, ft-lb, or in-lb), making it more adaptable for international or diverse projects.

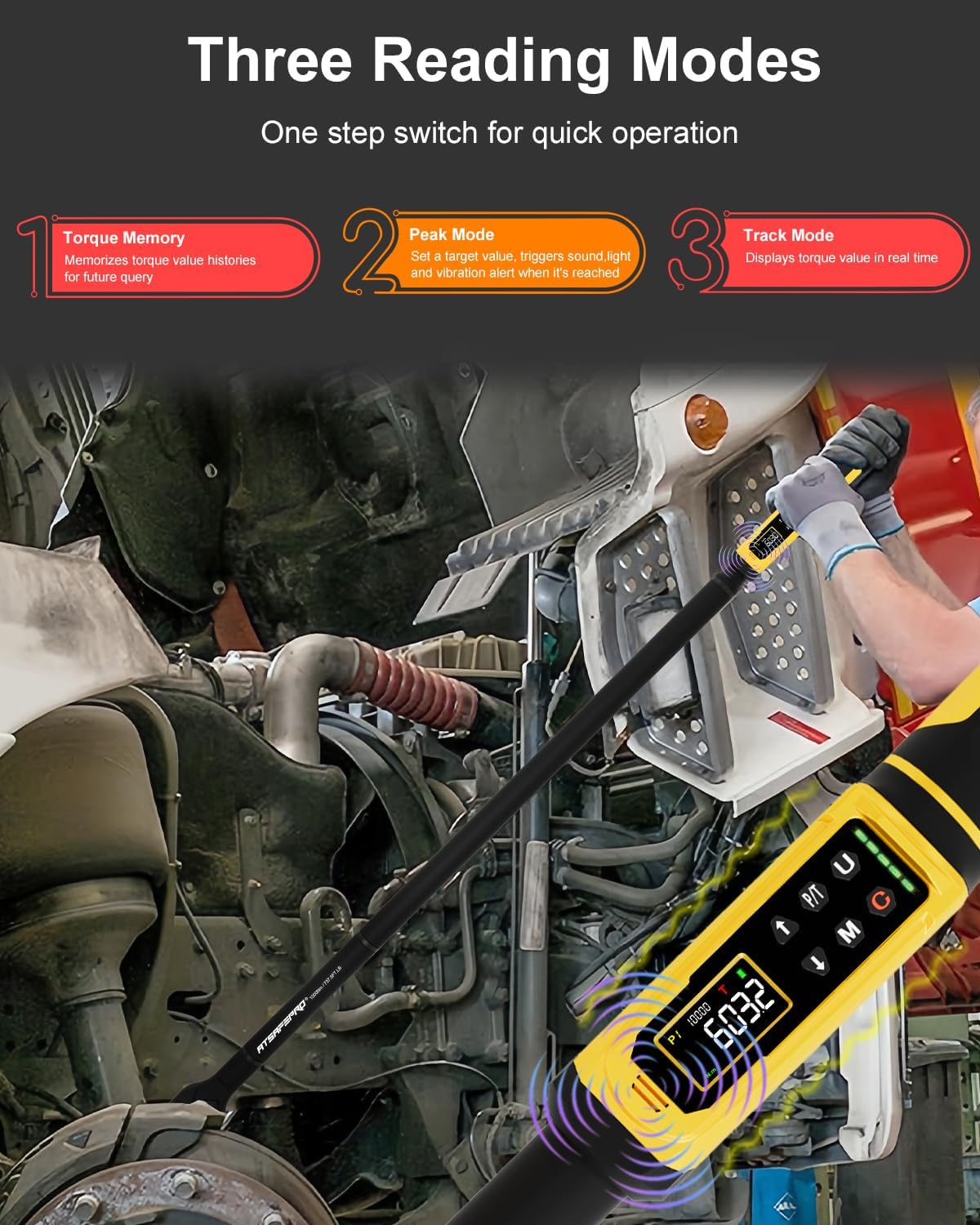

The ATsafepro Torque wrench's technology also incorporates overload protection and audible alerts, features that enhance user safety and efficiency. While Digital Torque wrenches may have these bells and whistles, they often come at a higher price point without the comprehensive kit that the ATsafepro provides, including the calibration tools. Mechanical Torque wrenches, conversely, are praised for their no-battery simplicity, but this comes at the cost of lacking the fine-tuned accuracy needed for high-stakes applications like aerospace or medical device assembly. By blending digital precision with mechanical reliability, the ATsafepro Torque wrench offers a hybrid advantage, delivering faster setup times and fewer errors compared to purely mechanical options.

Versatility and Applications: Comparing Use Cases

Versatility defines the ATsafepro Torque wrench's appeal, making it suitable for a broad spectrum of tasks from bicycle repairs to heavy machinery maintenance. Its digital interface allows quick switching between settings, a flexibility that Mechanical Torque wrenches struggle to match due to their fixed calibration processes. For example, in automotive work, where torque specs vary widely across engine components, the ATsafepro enables precise adjustments on the fly, whereas a Mechanical Torque wrench might require multiple tools or recalibrations, slowing down workflows. Digital Torque wrenches perform comparably in this regard, but the ATsafepro's ergonomic edge and included carrying case make it more user-friendly for mobile professionals who need to carry their toolkit across job sites.

In DIY scenarios, the ATsafepro Torque wrench democratizes professional-grade results, allowing enthusiasts to achieve factory-like tightness without the guesswork inherent in Mechanical Torque wrenches. While a Digital Torque wrench might appeal to tech-savvy users, its potential for electronic glitches in dusty or humid conditions contrasts with the ATsafepro's resilient build. Professionals in fields like plumbing or electrical work will appreciate how the ATsafepro reduces rework—over-tightening a bolt with a Mechanical Torque wrench could strip threads, leading to costly repairs, whereas the ATsafepro's alerts prevent such mishaps. Overall, its multifunctionality positions it as a more comprehensive solution than the specialized focus of its digital or mechanical peers.

User Experience and Value: Weighing the Pros and Cons

From a user experience standpoint, the ATsafepro Torque wrench prioritizes ease of use with its intuitive digital controls and clear visual feedback, outpacing the tactile-only operation of Mechanical Torque wrenches that demand more experience to master. Beginners might find the click of a Mechanical Torque wrench ambiguous, while seasoned users could prefer its simplicity for quick jobs. However, for precision-critical tasks, the ATsafepro's data logging capability—tracking torque history—provides an edge over standard Digital Torque wrenches, which may not include such advanced tracking without extra software.

Value-wise, investing in the ATsafepro Torque wrench yields long-term savings through its durability and included accessories, like the Allen key for maintenance, which aren't always bundled with Mechanical or basic Digital Torque wrenches. While Mechanical options are cheaper upfront, their potential for inaccuracy can lead to higher indirect costs from errors. Digital Torque wrenches match the ATsafepro in tech features but often lack the ergonomic refinements that make extended use comfortable. For professionals aiming to boost efficiency and for DIYers seeking reliability, the ATsafepro Torque wrench represents a smart upgrade, combining the best of both worlds in a package that's both professional and approachable.

Conclusion: Why Choose the ATsafepro Torque Wrench?

Ultimately, when pitting the ATsafepro Torque wrench against Digital and Mechanical Torque wrenches, its blend of precision, comfort, and versatility emerges as the clear winner for most users. Whether you're tightening lug nuts on a vehicle or assembling furniture with exact specifications, this tool's digital accuracy surpasses mechanical limitations, while its robust design addresses common digital pitfalls. With thoughtful inclusions like the carrying case and calibration key, the ATsafepro Torque wrench isn't just a tool—it's an investment in quality work. For anyone serious about their projects, it's time to make the switch and experience the difference in torque application.