Understanding the Digital Caliper: A Precision Measurement Essential

In the realm of precision engineering and manufacturing, the digital caliper stands as a cornerstone tool for accurate linear measurements. This device, often referred to as an electronic caliper, replaces traditional vernier calipers with digital readouts for enhanced readability and speed. A digital caliper typically features sliding jaws that clamp onto an object to measure internal, external, depth, and step dimensions with resolutions as fine as 0.01 mm. Its electronic display eliminates parallax errors common in analog versions, making it indispensable in fields like machining, quality control, and metrology. For professionals seeking reliability, innovations such as the GODESON digital caliper exemplify how modern design integrates durability with functionality. Equipped with advanced sensors, these tools convert mechanical motion into digital signals, ensuring measurements are not only precise but also repeatable under varying conditions.

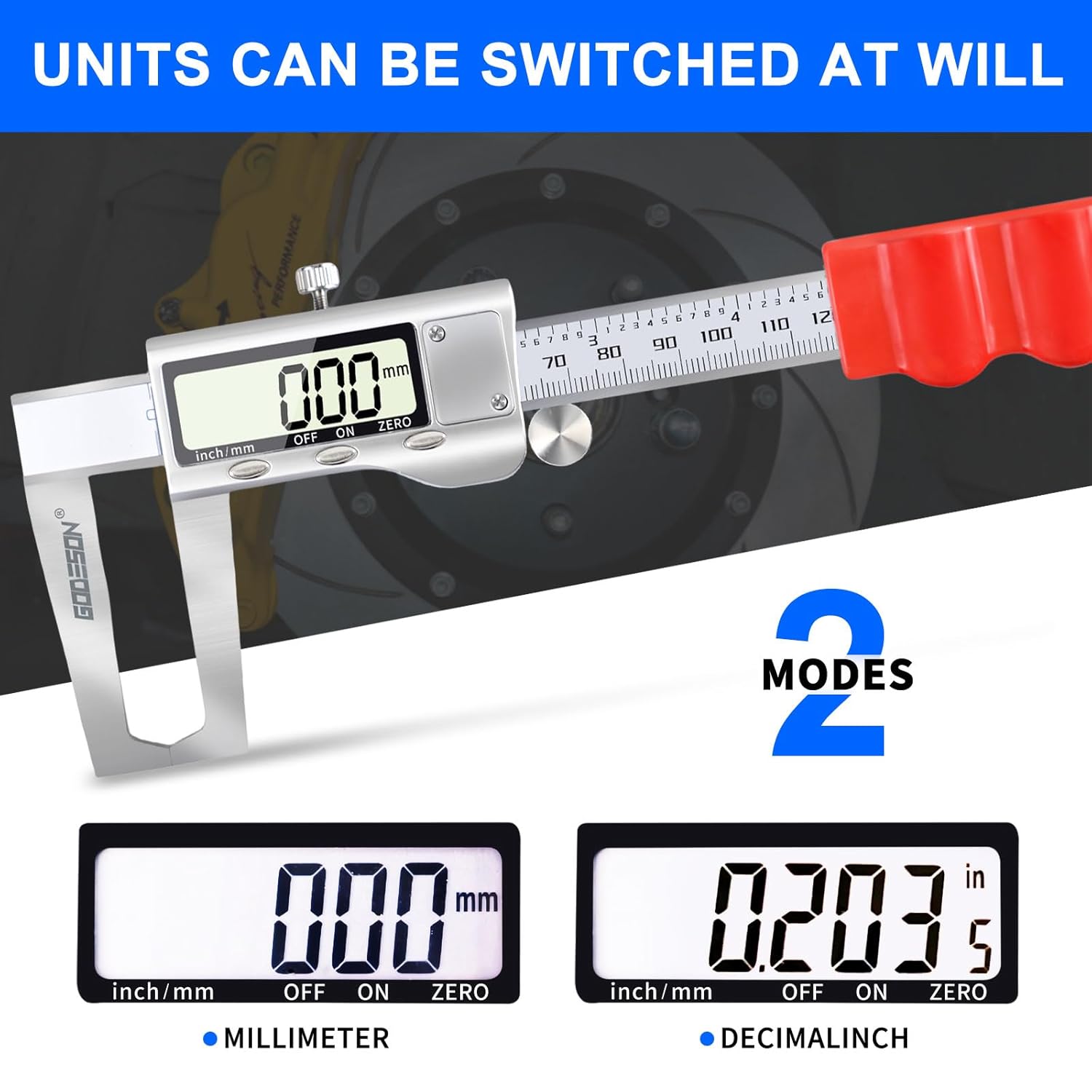

The operational principle of a digital caliper revolves around a capacitive or inductive linear encoder. As the jaw slides along the main scale, the encoder detects position changes and translates them into numerical values on an LCD screen. This technology allows for quick unit conversions between millimeters and inches, a feature that streamlines workflows in international standards-compliant environments. Beyond basic functionality, many models include absolute measurement modes that retain zero settings even after power-off, reducing setup time. When evaluating options, factors like jaw length—ranging from 100 mm to 300 mm—and battery life become critical. The GODESON digital caliper, for instance, incorporates such features to cater to both workshop rigor and field portability, highlighting its role in elevating measurement accuracy.

Key Features and GODESON Caliper Specifications

Delving into GODESON caliper specifications reveals a commitment to engineering excellence tailored for demanding applications. The GODESON digital caliper is engineered with a stainless steel body, providing corrosion resistance and structural integrity under mechanical stress. Its IP54 waterproof protection rating ensures resilience against water splashes, oil ingress, and dust accumulation, making it suitable for environments like automotive repair shops or outdoor construction sites. Specifications typically include a measurement range of 0-150 mm (or 0-6 inches), with a least count of 0.01 mm for unparalleled precision. The device's thumbroller and fine adjustment wheel facilitate smooth operation, allowing users to achieve exact positioning without slippage.

Advanced GODESON caliper specifications extend to its display and power management. The large LCD screen offers high contrast visibility, even in low-light conditions, and supports data hold functions to freeze readings for documentation. Powered by a standard SR44 battery, it boasts extended runtime, often exceeding 12 months under normal use. Jaw configurations in the GODESON digital caliper include stepped external jaws for better grip on cylindrical objects and rounded internal jaws for delicate measurements, minimizing surface damage. Additionally, the zero-setting capability at any position enables relative measurements, a vital feature for comparative tasks in assembly lines. These specifications underscore the tool's versatility, from hobbyist projects to professional CNC machining, where tolerances below 0.05 mm are routine.

Environmental durability is a hallmark of the GODESON caliper specifications. With its IP54 enclosure, the device withstands non-submersive water exposure and particulate matter, adhering to IEC 60529 standards. This protection is achieved through sealed gaskets around the moving parts and a robust casing that maintains calibration integrity over time. For calibration, GODESON recommends periodic checks using gauge blocks traceable to NIST standards, ensuring metrological traceability. The caliper's low power consumption and auto-off feature further enhance its practicality, conserving energy during intermittent use. In technical comparisons, the GODESON digital caliper outperforms many competitors in terms of jaw parallelism—maintained within 0.02 mm—reducing measurement uncertainty and boosting confidence in critical applications like aerospace component inspection.

Applications and Technical Advantages of the Digital Caliper

The digital caliper's applications span a wide array of technical domains, from mechanical engineering to electronics prototyping. In manufacturing, it is used for verifying part dimensions against CAD models, ensuring compliance with ISO 2768 tolerances. The GODESON digital caliper, with its precise readout, excels in such scenarios by providing instant feedback that accelerates quality assurance processes. For depth measurements, the integrated probe extends into bores or recesses, offering accuracy comparable to dedicated depth micrometers but with greater portability. In educational settings, it serves as an introductory tool for teaching mensuration principles, allowing students to explore concepts like least count and systematic errors hands-on.

Technically, the advantages of a digital caliper like the GODESON model lie in its integration of microcontroller technology for signal processing. This enables features such as preset functions for batch measurements and output interfaces (like USB or RS-232 in advanced variants) for data logging into software like Excel or SPC systems. Error sources, such as thermal expansion of the scale, are mitigated through low-thermal-coefficient materials, maintaining accuracy across temperature ranges of 0-40°C. Compared to dial calipers, the digital version reduces human error by 30-50%, as per industry studies, making it a preferred choice in high-volume production. The GODESON digital caliper's ergonomic design, with a non-slip grip and lightweight construction (around 150g), further enhances user efficiency during prolonged sessions.

In woodworking and metalworking, the tool's step measurement capability proves invaluable for checking grooves or shoulders, where traditional rulers fall short. For hobbyists in 3D printing, it aids in calibrating nozzle offsets and bed leveling, ensuring print fidelity. The GODESON caliper specifications support these diverse uses by balancing precision with ruggedness, including shock-resistant construction to handle accidental drops from workbench heights. Maintenance involves simple cleaning with isopropyl alcohol to preserve the IP54 seal's efficacy, and regular battery replacement to avoid display glitches. Overall, the digital caliper represents a fusion of electromechanical engineering that democratizes high-precision measurement, empowering users across skill levels.

Maintenance, Selection, and Future Trends in Digital Calipers

Proper maintenance of a digital caliper is crucial for sustained performance. For the GODESON digital caliper, avoid exposing it to extreme temperatures or magnetic fields that could disrupt the encoder. Calibration should be performed annually or after heavy use, using certified standards to verify accuracy within ±0.03 mm. Cleaning the jaws with a soft cloth prevents buildup that might affect clamping force, and storing it in a protective case preserves the finish. When selecting a model, consider the GODESON caliper specifications for IP-rated protection if working in harsh environments, or opt for extended-range versions for larger components.

Looking ahead, future trends in digital calipers point toward wireless connectivity and AI-assisted measurements. Bluetooth-enabled models, like potential evolutions of the GODESON digital caliper, could transmit data to cloud platforms for real-time analytics, revolutionizing predictive maintenance in Industry 4.0 setups. Integration with AR glasses for overlaying measurements on physical objects is another frontier, enhancing visualization in complex assemblies. As materials science advances, expect even lighter carbon-fiber reinforced bodies without compromising strength. These developments ensure the digital caliper remains a vital instrument, continually adapting to the evolving demands of precision engineering.

In summary, the digital caliper, particularly exemplified by the GODESON digital caliper and its detailed specifications, offers unmatched reliability and versatility. Whether for professional or personal use, investing in such a tool guarantees accuracy that drives efficiency and innovation. With over 800 words of technical insight, this exploration underscores its indispensable role in modern measurement practices.