Pneumatic air chuck systems are essential tools for anyone involved in automotive work, manufacturing, or DIY projects, offering precise control and efficiency in handling air pressure. This guide will walk you through everything you need to know about selecting, using, and maintaining these devices, with a focus on innovative features like closed flow designs that enhance performance and safety.

Understanding the Basics of Air Chucks

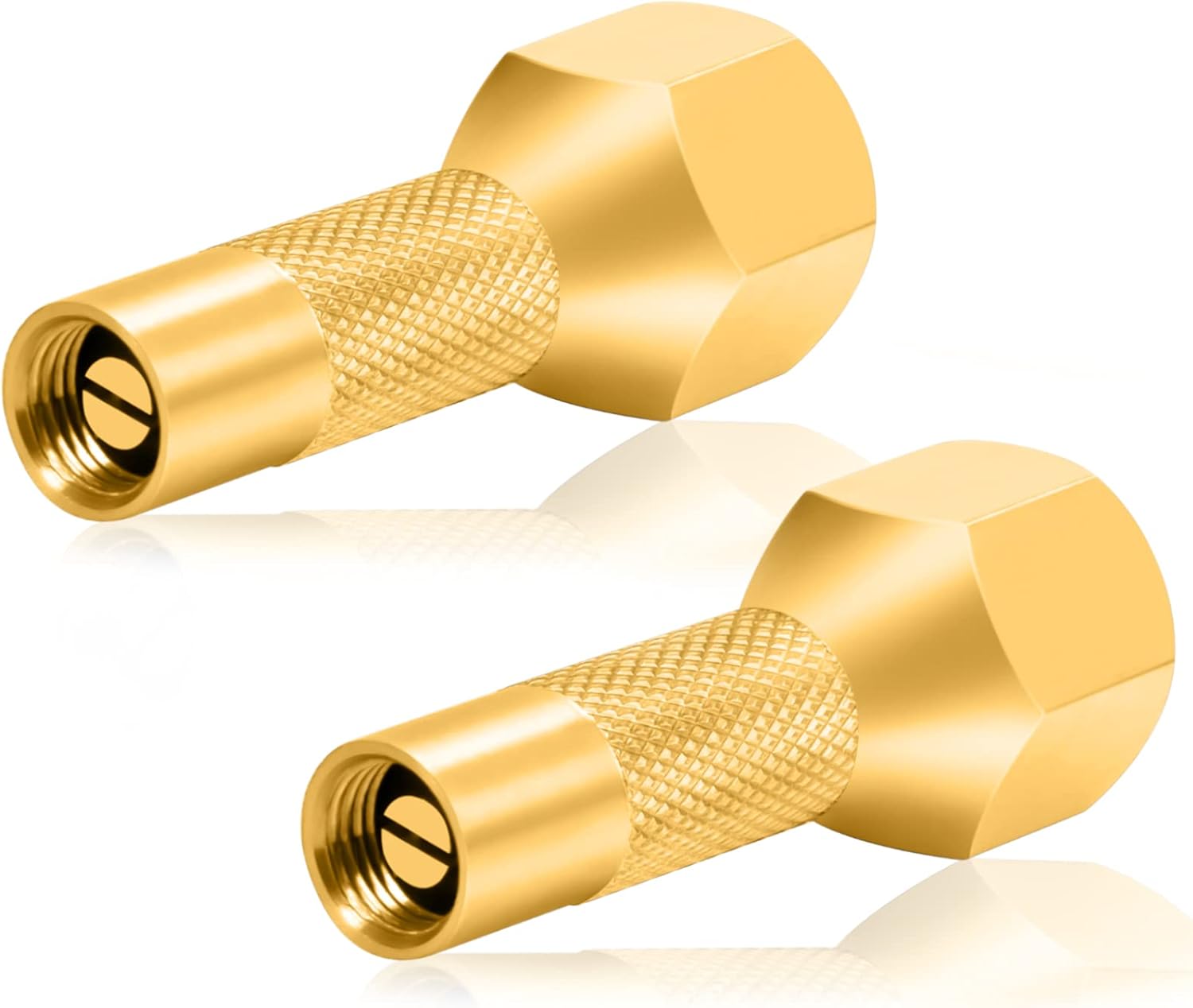

Air chucks are fundamental components in pneumatic systems, designed to connect air hoses to valves for inflating tires, operating tools, or managing pressure in various applications. A pneumatic air chuck, for instance, uses compressed air to secure objects firmly, making it ideal for tasks that require stability and precision. These devices work by creating a seal that allows air to flow only when needed, preventing leaks and ensuring optimal performance. When choosing an air chuck, consider factors like material durability—such as brass construction—which offers resistance to corrosion and wear. The closed flow design in modern air chucks means air is released only upon engagement, providing better control and reducing waste. This feature is particularly useful in professional settings where efficiency is key, and it helps maintain consistent pressure levels for tasks like tire inflation or pneumatic tool operation.

Selecting the Right Air Chuck for Your Needs

When it comes to picking the perfect air chuck, start by evaluating your specific requirements. An air chuck should be selected based on its compatibility with your equipment, such as fitting standard valve stems or specialized connectors. For enhanced security, a locking air chuck is a great option, as it features a mechanism that locks onto the valve to prevent accidental disconnection during use. Locking air chucks are especially beneficial in high-vibration environments, like automotive repair shops, where maintaining a secure connection is crucial for safety and efficiency. Pneumatic air chuck models with a brass body, like the one featuring a closed flow design, provide not only durability but also a polished aesthetic that stands up to frequent use. Factors to consider include the chuck's flow rate, which affects how quickly you can pressurize a system, and its ease of use, such as ergonomic handles for better grip. Air chucks with intelligent designs minimize air loss, making them more environmentally friendly and cost-effective over time. If you're an enthusiast or professional, opting for a high-quality air chuck can significantly improve your workflow, ensuring that tasks are completed with minimal hassle.

How to Properly Use a Locking Air Chuck

Using a locking air chuck effectively involves a few straightforward steps that can enhance your pneumatic operations. First, ensure your air compressor is set to the appropriate pressure level for the task at hand, typically between 30 to 120 PSI depending on the application. To begin, attach the locking air chuck to the air hose by screwing it securely onto the fitting, making sure it's tightened to avoid leaks. When connecting to a valve, such as on a tire or pneumatic tool, align the chuck properly and press it firmly onto the stem until you hear or feel the lock engage. This is where the locking feature shines, as it holds the connection in place without needing constant pressure from your hand. Once engaged, turn on the air flow and monitor the pressure gauge to achieve the desired level. For pneumatic air chuck systems, the closed flow design ensures that air isn't wasted, allowing for precise control during inflation or operation. Remember to release the lock gently after use by twisting or pressing the release mechanism, then disconnect carefully to prevent any sudden air bursts. This method not only extends the life of your equipment but also reduces the risk of injury. In practice, mastering this technique can save time and improve accuracy, whether you're inflating tires for a road trip or powering tools in a workshop.

Maintenance and Benefits of Pneumatic Air Chucks

Proper maintenance is key to getting the most out of your air chuck and ensuring it lasts for years. Start by regularly inspecting the chuck for signs of wear, such as cracks in the brass body or worn seals, and replace any damaged parts immediately to maintain safety and performance. Clean the chuck after each use by wiping it down with a dry cloth to remove debris, and occasionally lubricate the moving parts with a suitable pneumatic lubricant to keep it operating smoothly. A locking air chuck benefits from this routine because its locking mechanism relies on precise components that can degrade over time. Air chucks with closed flow designs offer additional advantages, like reduced air loss, which translates to lower operating costs and better energy efficiency. One of the primary benefits of a pneumatic air chuck is its versatility; it can be used across various industries, from automotive to manufacturing, providing reliable performance in diverse scenarios. For instance, in a DIY setting, it allows enthusiasts to handle tasks with professional-grade precision, while professionals appreciate the durability and style it brings to their toolkit. By incorporating these maintenance practices, you'll extend the lifespan of your equipment and enjoy consistent results. Overall, investing in a quality air chuck not only streamlines your pneumatic tasks but also enhances safety and efficiency, making it an indispensable tool for any project.

Advanced Tips and Troubleshooting for Air Chucks

If you encounter issues with your air chuck, such as inconsistent pressure or difficulty locking, troubleshooting can often resolve the problem quickly. First, check for blockages in the air hose or chuck itself, as debris can impede airflow and reduce effectiveness. Ensure that the locking air chuck is properly aligned with the valve; misalignment is a common cause of leaks. Pneumatic air chuck users should also verify that the compressor's regulator is functioning correctly, as faulty settings can lead to over- or under-inflation. Another tip is to store your air chuck in a cool, dry place to prevent corrosion, especially if it's made of brass, which is prized for its longevity but can tarnish if exposed to moisture. Air chucks with innovative features like closed flow systems are less prone to common problems, but if you notice air escaping when not in use, it might indicate a worn seal that needs replacement. For optimal performance, consider upgrading to models with additional safety features, such as built-in pressure relief valves. By following these advanced tips, you'll minimize downtime and maximize the utility of your equipment, ensuring that your pneumatic tasks are always handled with ease and precision. Whether you're a beginner or an expert, these strategies will help you get the most out of your air chuck investments.