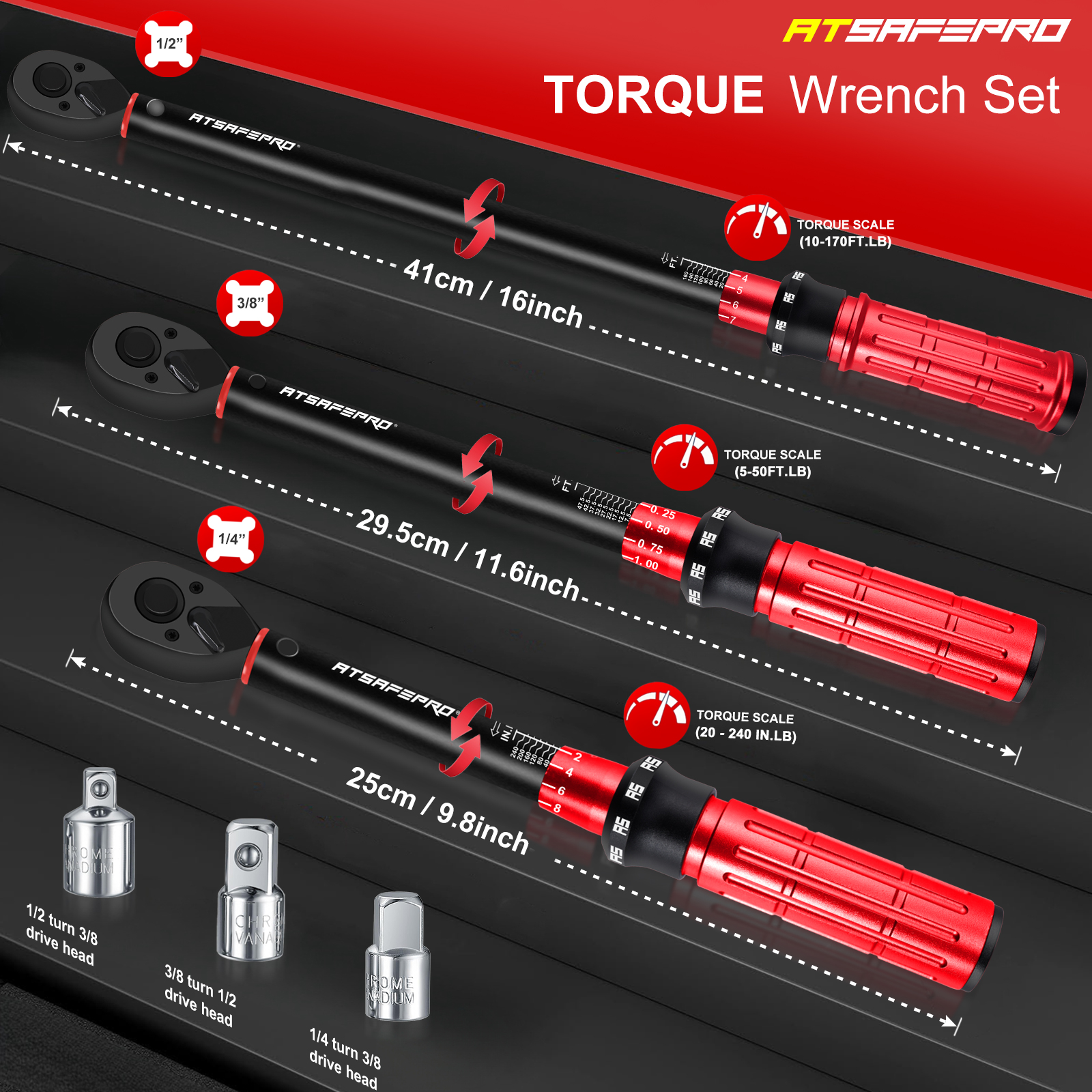

Ergonomic Torque Wrenches: Precision Meets Comfort in Professional Fastening

Why Ergonomics Matter in Torque Tools

Torque wrenches are essential for precision fastening, but in high-volume or long-duration work, tool design can impact both performance and operator health. Repetitive strain injuries (RSIs) are common in workshops and assembly lines, and poorly designed tools can lead to reduced accuracy from operator fatigue.

An ergonomic torque wrench is engineered to fit the hand comfortably, reduce muscle strain, and provide better control. By minimizing the physical effort required, it allows technicians to maintain consistent torque application for longer periods.

Key Features of an Ergonomic Torque Wrench

-

Contoured Grip Handle – Distributes force evenly across the hand, reducing pressure points.

-

Non-Slip Surface – Provides secure handling even in oily or wet environments.

-

Balanced Weight Distribution – Reduces wrist strain and improves control.

-

Smooth Adjustment Mechanism – Requires less effort to set torque values accurately.

-

Clear Readouts – Easy-to-read scale or digital display positioned for minimal head/hand movement.

Real-World Applications and Benefits

Automotive Service Centers

Mechanics often tighten dozens of fasteners daily. An ergonomic torque wrench reduces wrist fatigue during repetitive tasks such as engine assembly, suspension work, and brake installation, while maintaining high torque accuracy.

Industrial Assembly Lines

In manufacturing environments where workers repeat the same fastening motions thousands of times per shift, ergonomic tools improve productivity and reduce injury risk. A comfortable grip ensures consistent torque without overexertion.

Field Maintenance and Repair

Technicians working in awkward positions — such as on ladders, under vehicles, or in confined spaces — benefit from the improved handling and leverage that ergonomic designs provide.

Cycling and Motorsport Applications

For precision components like carbon fiber bike frames or race car engine parts, maintaining control while applying the correct torque is critical. Ergonomic handles give the fine control needed for delicate tasks.

Ergonomic Torque Wrench vs Standard Torque Wrench: The 5 Key Differences That Matter to Professionals

| Key Difference | Ergonomic Torque Wrench | Standard Torque Wrench |

|---|---|---|

| Grip Comfort | A bicycle mechanic adjusts dozens of carbon fiber components daily; a contoured, soft-grip handle keeps the hand relaxed all day. | A straight, hard handle leaves pressure marks on the palm after prolonged use, reducing grip strength. |

| Non-Slip Handling | An auto technician wearing oily gloves can still maintain a firm hold thanks to textured, non-slip material. | Smooth metal surfaces become slippery with oil, increasing the risk of losing control mid-task. |

| Weight Balance | On an industrial assembly line, balanced weight distribution reduces wrist strain during four-hour shifts. | A front-heavy tool causes noticeable wrist fatigue after repeated lifts and turns. |

| Stability Under Load | During precision assembly, ergonomic handles minimize hand tremor, keeping torque values consistent. | Inconsistent grip pressure causes small variations in torque, which can affect product quality. |

| Adjustment Ease | While tuning automotive suspension, clear markings and smooth adjustment allow fast, accurate torque settings. | Hard-to-read markings and uneven resistance make torque setting slower and prone to errors. |

ATSAFEPRO: Where Comfort Meets Accuracy

ATSAFEPRO ergonomic torque wrenches are engineered not only for ISO-certified torque accuracy but also for long-term operator comfort — an essential factor in productivity and quality control.

B2B Advantages:

-

Bulk Supply Capability: Scalable production and stock availability for large workshop chains, OEM assembly plants, and fleet service providers.

-

Custom Specification Service: Torque ranges, handle designs, and branding tailored to client needs.

-

Calibration & Certification: All tools delivered with traceable calibration certificates, with optional on-site or scheduled recalibration services.

-

Durability for Industrial Environments: Impact-resistant casing, corrosion-resistant materials, and sealed mechanisms for harsh working conditions.

-

Operational Cost Savings: Reduced worker fatigue and fewer torque-related rework errors translate to higher efficiency and lower downtime.

Professional Support Services:

-

Technical Consultation: Pre-purchase tool selection guidance to match specific assembly requirements.

-

After-Sales Training: Usage and care training for technicians to ensure optimal tool performance and longevity.

-

Global Distribution Network: Reliable logistics and shipping support for international B2B customers.

With ATSAFEPRO, you don’t just get a torque wrench — you get a precision fastening solution backed by professional-grade support.View our range of ergonomic torque wrenches on the ATSAFEPRO product page, or visit our homepage for more precision fastening tools. For bulk orders, OEM customization, or technical consultation, contact us today.