Discover the Precision of the ATSafePro Torque Wrench

In the world of precision engineering and automotive maintenance, the ATSafePro Torque Wrench stands out as an indispensable tool for achieving accurate and reliable results. Whether you're a professional mechanic or a dedicated DIY enthusiast, this versatile wrench ensures that every fastening job is done right, preventing over-tightening or under-tightening that could lead to equipment failure. The ATSafePro Torque Wrench combines durability with user-friendly design, making it a go-to choice for tasks ranging from minor adjustments to heavy-duty assembly.

Exploring the ATSafePro Torque Wrench Set

The ATSafePro Torque Wrench set is thoughtfully designed to cater to a variety of needs, featuring three distinct sizes that cover a broad spectrum of applications. Each wrench boasts a striking red finish that not only enhances visibility in a busy workshop but also signifies its robust construction. The ergonomic black knurled grips provide a secure and comfortable hold, reducing hand fatigue during extended use. This set is particularly praised for its adaptability, allowing users to switch between different drive sizes seamlessly, which is crucial for tackling diverse projects without needing multiple specialized tools.

Starting with the largest in the lineup, this 41 cm (16.1 inches) wrench equipped with a 1/2-inch drive offers a torque range of 10-170 FT.LB. It's perfectly suited for heavy-duty tasks such as engine repairs or suspension work on vehicles, where significant force is required to secure large bolts. The clear torque scale etched along the body allows for precise settings, and the quick-lock mechanism ensures the selected torque holds firm under pressure. This level of accuracy helps maintain the integrity of components, extending their lifespan and ensuring safety in high-stakes environments.

Moving to the medium-sized option, the 30 cm (11.8 inches) wrench with a 3/8-inch drive delivers torque from 5-50 FT.LB. This makes it ideal for intermediate applications like brake caliper installations or assembly of machinery parts that demand moderate precision. The design emphasizes ease of use, with smooth adjustments that let technicians fine-tune settings on the fly. Professionals appreciate how this wrench balances power and control, making it a staple in automotive shops and manufacturing facilities alike.

The smallest wrench in the set, measuring 24 cm (9.4 inches) with a 1/4-inch drive, provides a torque range of 20-240 IN.LB, tailored for finer adjustments such as electronics assembly or delicate automotive components. Its compact size allows access to tight spaces, while the same high-quality features ensure consistent performance. This versatility within the set means that from small-scale hobbies to professional calibrations, the ATSafePro Torque Wrench adapts effortlessly to the task at hand.

Comparing Digital and Mechanical Torque Wrenches

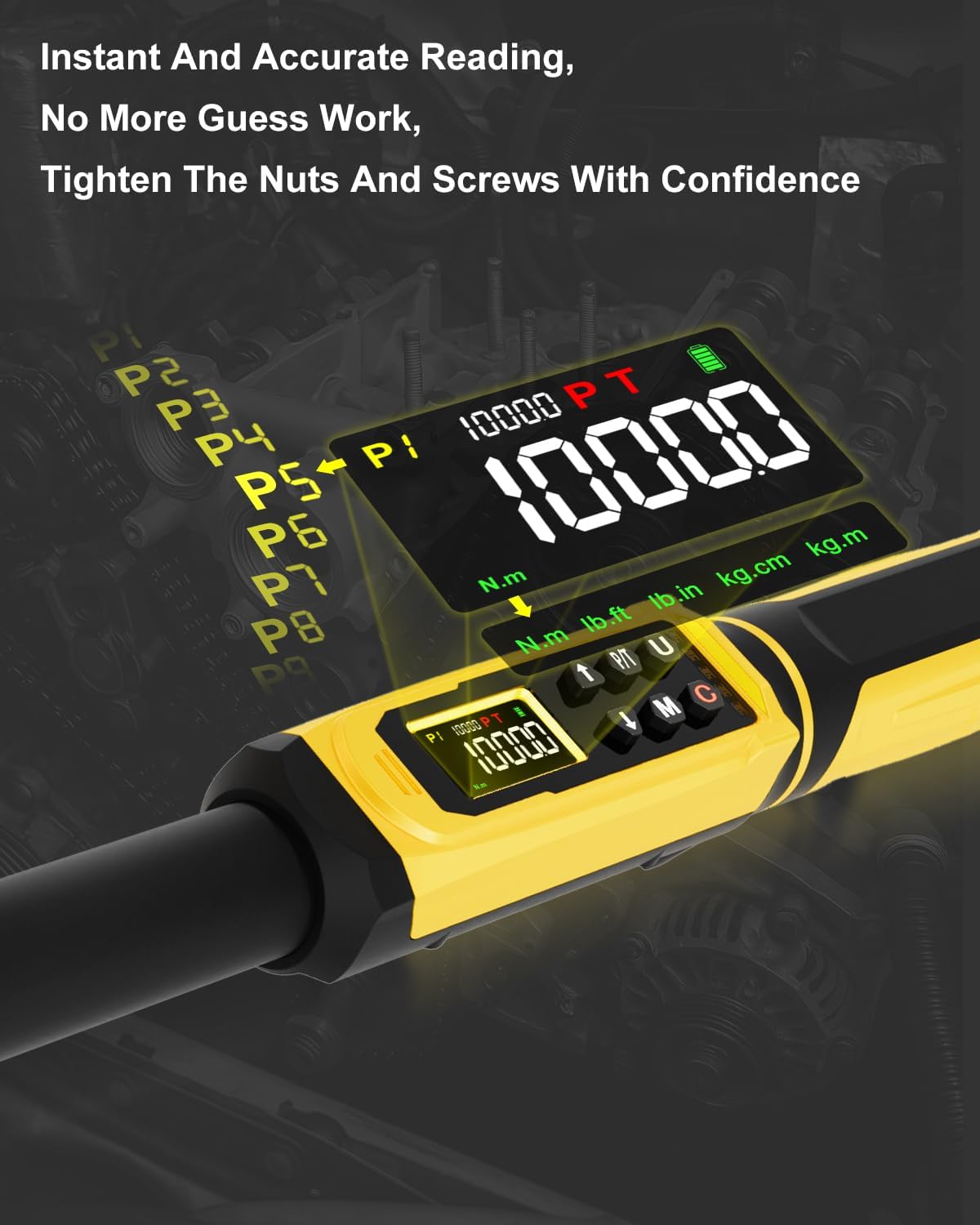

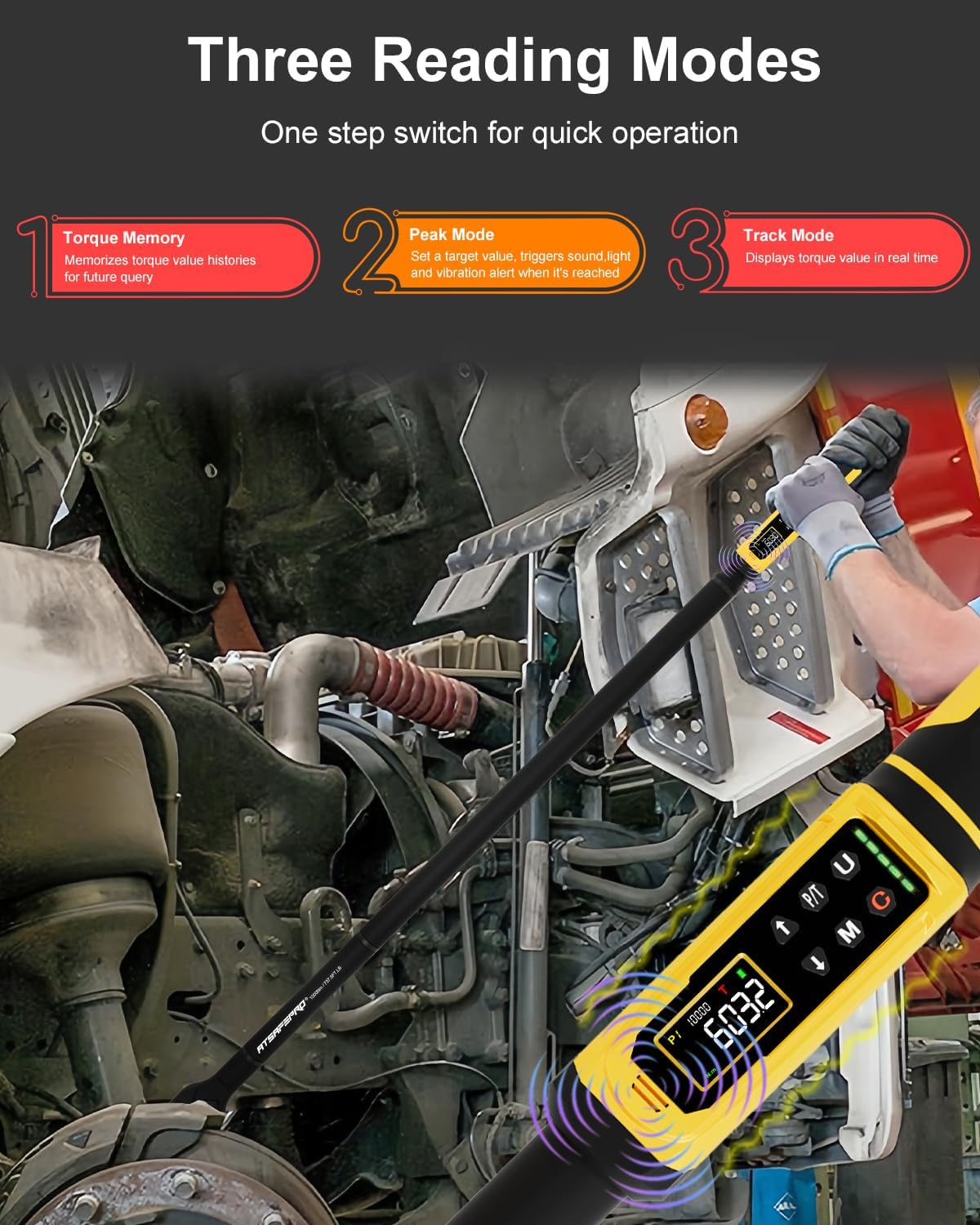

When selecting a torque wrench, understanding the differences between digital and mechanical options can guide you toward the best fit for your needs. A Digital Torque Wrench often incorporates electronic displays and sensors for real-time feedback, alerting users with audible beeps or visual cues when the desired torque is reached. This technology is invaluable in precision-critical fields like aerospace or medical device manufacturing, where even minor deviations can have significant consequences. Digital models typically offer data logging capabilities, allowing for detailed records of torque applications, which is a boon for quality control and compliance with industry standards.

In contrast, the Mechanical Torque Wrench, like those in the ATSafePro set, relies on proven analog mechanisms such as click or beam styles for torque measurement. The click-type, which is the foundation of the ATSafePro design, provides a tactile 'click' signal upon reaching the set torque, offering reliability without the need for batteries or electronics. This makes mechanical wrenches more rugged and suitable for harsh workshop conditions where dust, moisture, or impacts might compromise digital components. The ATSafePro Torque Wrench exemplifies this mechanical excellence, with its calibrated scales and lock mechanisms ensuring long-term accuracy without the complexity of digital interfaces.

Choosing between a digital torque wrench and a mechanical one often comes down to the specific demands of your work. For environments requiring frequent documentation or ultra-precise readings in controlled settings, digital variants shine. However, for everyday automotive and general engineering tasks, the straightforward, durable nature of a mechanical torque wrench like the ATSafePro proves more practical and cost-effective. The ATSafePro set bridges this gap by providing mechanical precision in a comprehensive package, eliminating the guesswork in selection.

Enhancing Your Toolkit with Adaptability and Features

What truly elevates the ATSafePro Torque Wrench set is its inclusion of drive head adapters, which enhance its adaptability across various projects. These adapters—1/2 to 3/8-inch, 3/8 to 1/2-inch, and 1/4 to 3/8-inch—allow seamless transitions between wrench sizes, maximizing the utility of the entire set. Imagine working on a car restoration: you can start with the large wrench for chassis bolts, switch adapters to the medium for engine components, and finish with the small one for trim fasteners, all without reaching for separate tools. This interconnected design streamlines workflows, saving time and reducing clutter in your toolbox.

Durability is another cornerstone of the ATSafePro Torque Wrench. Constructed from high-grade materials, these wrenches resist corrosion and wear, even after repeated use in demanding conditions. The vibrant red coating not only adds a professional aesthetic but also protects against scratches and chips. Users often highlight the comfort of the knurled grips, which provide better traction in oily or greasy environments, preventing slips that could lead to inaccurate torque application. Regular maintenance is straightforward, involving simple cleaning and occasional calibration checks to maintain peak performance.

For those new to torque wrenches, integrating the ATSafePro into your routine begins with understanding proper usage. Always set the torque to zero when not in use to preserve the internal spring, and store them in a protective case to avoid damage. The set's clear scales make it accessible for beginners, while experienced users value the consistency that prevents common pitfalls like stripped threads or warped parts. Whether you're assembling furniture, repairing bicycles, or overhauling engines, this tool set empowers you with confidence in every turn.

Why the ATSafePro Torque Wrench is Essential for Professionals and Enthusiasts

In summary, the ATSafePro Torque Wrench represents a pinnacle of mechanical innovation, blending style, precision, and practicality into one cohesive set. Its range of sizes and adapters make it versatile enough for any project, while the robust mechanical design ensures reliability in the field. Compared to digital alternatives, it offers a no-fuss approach that's ideal for hands-on tasks, appealing to those who prioritize tactile feedback and longevity. Investing in the ATSafePro Torque Wrench means equipping yourself with tools that not only perform but also endure, fostering efficiency and safety in your work. As you explore options in digital torque wrenches or mechanical variants, the ATSafePro stands as a testament to quality engineering, ready to tackle whatever challenges come your way.

This comprehensive set is more than just tools; it's a gateway to professional-grade results at home or on the job. With its thoughtful features and enduring build, the ATSafePro Torque Wrench set is poised to become the cornerstone of your toolkit, delivering torque with unmatched accuracy every time.