In the world of mechanics, whether you're a professional technician or a dedicated DIY enthusiast, precision is not just a goal; it's a necessity. The difference between a perfectly secured bolt and one that's too loose or too tight can mean the difference between reliability and failure. This is where the right equipment becomes indispensable. This guide is designed to walk you through mastering one of the most crucial instruments in any modern toolkit: the ATsafepro torque wrench, ensuring every task you undertake is completed to exact specifications for ultimate safety and performance.

Unboxing Your ATsafepro Torque Wrench Set

Upon receiving your new ATsafepro set, the first thing you'll notice is the robust and well-organized carrying case. This isn't just for show; it's designed to protect your precision instruments from damage and keep them organized. Opening the case reveals a stunning set of three torque wrenches, each finished in a striking red that makes them easy to spot in a busy workshop. Alongside the wrenches, you'll find a set of chrome vanadium extensions, adding a layer of versatility right out of the box. The wrenches themselves feel substantial and well-balanced in your hand. The black handle features an ergonomic, textured grip that provides excellent control and comfort, minimizing fatigue during extended use and preventing slippage when applying higher torque values. This initial impression speaks volumes about the quality and thoughtful design invested in these tools.

Getting to Know Your New Torque Tool

Before you begin tightening fasteners, it's important to understand what makes this specialized torque tool so essential. Unlike a standard ratchet, a torque wrench is a calibration instrument designed to apply a specific amount of rotational force (torque) to a fastener. The ATsafepro wrenches feature a clearly marked, dual-range scale engraved on the shaft, displaying values in both foot-pounds (ft-lbs) and Newton-meters (Nm). This eliminates the need for conversion charts and accommodates a wider range of project specifications. At the base of the handle, a locking mechanism allows you to set your desired torque value. By twisting the handle, you align the indicator with the precise measurement on the scale, then lock it in place to prevent accidental changes during use. The most critical feature is the audible and tactile feedback mechanism. When the preset torque is reached, the wrench emits a distinct 'click' that you can both hear and feel, signaling you to stop applying force immediately.

How to Use Your ATsafepro Torque Wrench for Perfect Tightening

Using your new tool correctly is key to achieving accurate results. First, consult your vehicle's or equipment's service manual to find the correct torque specification for the fastener you are tightening. Next, select the appropriate wrench from the three-piece set that covers your required torque range. Attach the correct size socket and any necessary extensions. To set the torque, unlock the handle's base, and turn the handle until the zero mark on the handle scale lines up with your target measurement on the main shaft scale. For fine adjustments, use the markings on the handle itself. Once set, secure the locking mechanism. Position the socket onto the fastener and apply slow, steady pressure to the handle, pulling smoothly until you hear and feel the 'click'. As soon as the click occurs, stop pulling. It is crucial not to apply any further force, as this will result in over-tightening. Remember, a torque wrench is for tightening only; never use it to loosen bolts, as this can damage the internal calibration mechanism.

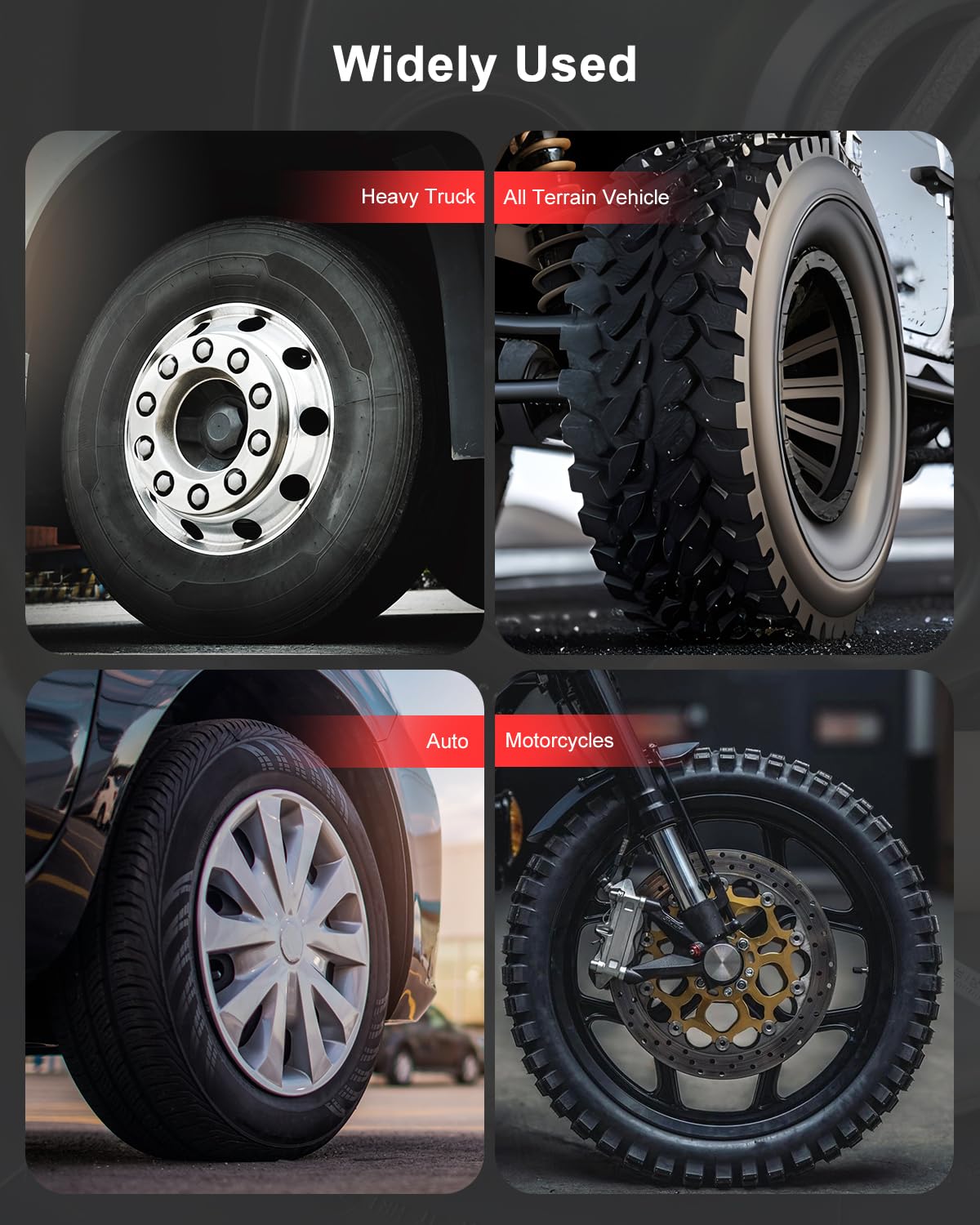

Versatile Applications for Your ATsafepro Tools

This three-piece set is not limited to a single type of job; it’s a comprehensive solution for a vast array of tasks. In the automotive world, these wrenches are perfect for tightening lug nuts, engine bolts, suspension components, and transmission bolts, where precise torque is critical for safety and proper function. For motorcycle and bicycle enthusiasts, the lower-range wrench provides the delicate precision needed for sensitive components like handlebars, seat posts, and engine casings. Beyond vehicles, these versatile ATsafepro tools are invaluable for general assembly, plumbing, and HVAC work, ensuring fittings are secure without being stripped or damaged. The inclusion of three different wrenches ensures you always have the right tool for the job, from low-torque applications requiring finesse to high-torque tasks demanding strength.

Caring for Your ATsafepro Torque Wrench

To ensure your ATsafepro torque wrench provides accurate readings for years to come, proper care and maintenance are essential. After each use, it is critically important to turn the handle back to the lowest torque setting before storing it. Leaving the spring compressed at a high setting can cause it to weaken over time, leading to inaccurate readings. Wipe the tool clean of any dirt, grease, or grime with a dry cloth. Always store the wrench in its protective case to shield it from impacts, dust, and moisture that could interfere with its mechanism. Avoid dropping the wrench, as a sharp impact can knock it out of calibration. For professionals who rely on absolute accuracy daily, it's a good practice to have the tool's calibration checked and adjusted periodically by a certified service.

Why Precision Matters: Final Thoughts

Mastering the use of a high-quality torque wrench is a fundamental skill that elevates the quality and safety of your mechanical work. The ATsafepro set provides the accuracy, durability, and versatility needed to tackle a wide range of projects with confidence. By understanding its features, following the correct usage procedures, and performing basic maintenance, you ensure that every fastener is secured to perfection. This commitment to precision not only protects the components you're working on but also provides peace of mind, knowing the job was done right every single time.