In the world of automotive repair and mechanical engineering, precision is not just a preference; it is a necessity. The correct application of force, or torque, to a fastener can mean the difference between a secure, reliable assembly and a catastrophic failure. For decades, professionals have relied on various types of torque tools to achieve this accuracy. However, as technology and manufacturing processes evolve, so do the instruments we use. The introduction of advanced systems like the ATsafepro torque wrench challenges us to compare the old guard with the new, evaluating where traditional tools stand and where modern innovations excel.

The Foundation: Traditional Torque Wrenches

For many years, the standard click-type or beam-style torque wrench has been a staple in toolboxes everywhere. The beam wrench, the simplest form, uses a pointer that moves along a scale as force is applied, indicating the torque value. Its advantage lies in its simplicity and durability, with no moving parts to wear out. However, it requires the user to view the scale from directly overhead to avoid parallax error, making it less precise in awkward positions. The click-type wrench became more popular due to its ease of use. The user sets a desired torque value on the handle, and upon reaching it, the wrench produces an audible and tactile 'click'. While convenient, these tools rely on an internal spring and cam mechanism that can wear down or fall out of calibration over time, potentially leading to inaccurate tightening without the user's knowledge. They are functional, but they represent a technology with inherent limitations in feedback, long-term accuracy, and user-centric design.

The Modern Contender: The ATsafepro Torque Wrench

Enter the modern era of precision instruments with the ATsafepro torque wrench set. This isn't just an iteration of an old design; it's a complete reimagining of what a torque tool can be. Crafted from high-strength chrome vanadium steel, the core of these tools is built for longevity and resistance to the rigors of professional use. Unlike the often ambiguous markings on older models, the ATsafepro features a high-contrast, clearly etched scale on the handle, making it incredibly easy to set a precise torque value. This eliminates guesswork and reduces the chance of human error. Furthermore, a robust and intuitive locking mechanism ensures that the setting remains fixed during use, preventing accidental adjustments that can compromise the integrity of the work. This level of reliability and user-friendliness sets a new standard for ATsafepro tools.

A Direct Comparison: Performance, Versatility, and User Experience

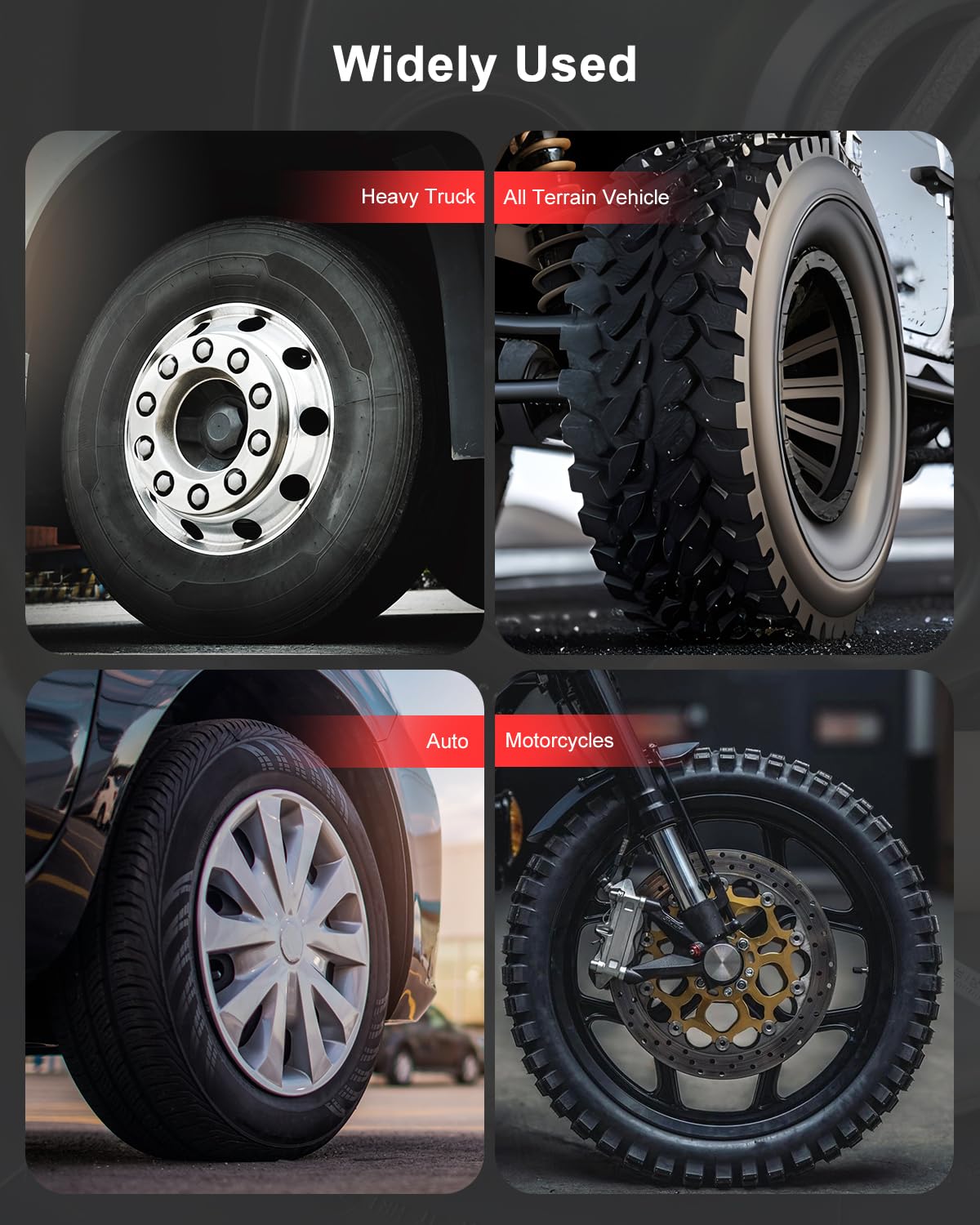

When placed side-by-side, the differences between traditional and modern tools become stark. In terms of precision, the ATsafepro torque wrench offers superior confidence. Its clear scale and secure lock provide a more dependable setup than a traditional click wrench, which may have internal wear, or a beam wrench, which is subject to user viewing error. Versatility is another area where the modern approach shines. Instead of purchasing multiple individual tools, the ATsafepro set provides three different wrench sizes and a comprehensive collection of chrome vanadium adapter sockets. This all-in-one solution, housed in a durable and organized case, is far more efficient and cost-effective for tackling a wide range of applications, from delicate engine components to heavy-duty industrial machinery. The user experience is perhaps the most noticeable upgrade. The ergonomic grip is designed for comfort and control, significantly reducing hand fatigue during long jobs. This thoughtful design, combined with the striking metallic red finish, proves that high-performance ATsafepro tools can also be aesthetically pleasing and a pleasure to use.

Making the Right Choice for Your Toolkit

Choosing the right torque tool ultimately depends on your specific needs and standards. For someone who only occasionally needs to tighten a nut, a basic, traditional wrench might seem sufficient. However, for the serious enthusiast, professional mechanic, or anyone who refuses to compromise on safety and quality, the advantages of a modern system are undeniable. The investment in a superior torque tool like the ATsafepro is an investment in accuracy, efficiency, and peace of mind. Properly torqued fasteners prevent stripped threads, damaged parts, and ensure that critical components like wheels and engine heads are securely fastened according to manufacturer specifications. The enhanced durability and reliable calibration of a high-quality tool also mean a longer service life, providing better value over time.

Conclusion: Embracing the Future of Precision

While traditional torque wrenches have served us well for generations, the evolution of tool design and manufacturing offers significant improvements that cannot be ignored. The ATsafepro torque wrench represents this evolution, moving beyond basic functionality to deliver a complete package of precision, durability, versatility, and user-focused design. By directly comparing its features against older models, it becomes clear that modern engineering provides a more reliable and efficient solution for critical tasks. For those who demand the best from their equipment, upgrading to an advanced system is not just a luxury but a logical step towards achieving better, safer, and more professional results in every project.