Which Tread Gauge Is Right for You? Dial, Digital, or Color Code?

Tire tread depth is directly linked to road grip, braking distance, and hydroplaning risk—especially in wet or winter conditions. But while many drivers overlook it, monitoring tread wear with a reliable tread gauge is just as important as checking tire pressure.

Whether you’re a workshop technician, fleet manager, or safety-conscious driver, ATSAFEPRO offers three precise tools to help you measure and manage tread depth the right way.

1. Dial Type Tread Depth Gauge

The dial tread gauge offers mechanical precision with a needle-based readout. It’s designed for users who want visible measurement increments, especially when recording multiple tire results.

Key Advantages:

-

Fine-scale increments (0–25 mm or 0–1 inch)

-

No battery required

-

Durable metal base and protective casing

-

Suitable for cars, trucks, trailers, and off-road vehicles

Use Case Example:

A vehicle inspection station checks 40+ cars daily. The dial-type gauge offers quick repeatable readings with tactile feedback, ideal for official reports and compliance.

2. Smart Color Code Tread Depth Gauge

This simple yet clever tool uses color coding—green, yellow, and red—to instantly show whether the tire tread is safe, borderline, or dangerous. It’s perfect for non-technical users who want clear visual guidance.

Key Advantages:

-

Easy-to-read color zones

-

No calibration or battery needed

-

Great for quick visual inspections

-

Lightweight and cost-effective

Use Case Example:

A delivery company checks tire conditions before each shift. Drivers use the color-coded gauge to assess wear without needing training or interpretation—saving time and reducing accidents.

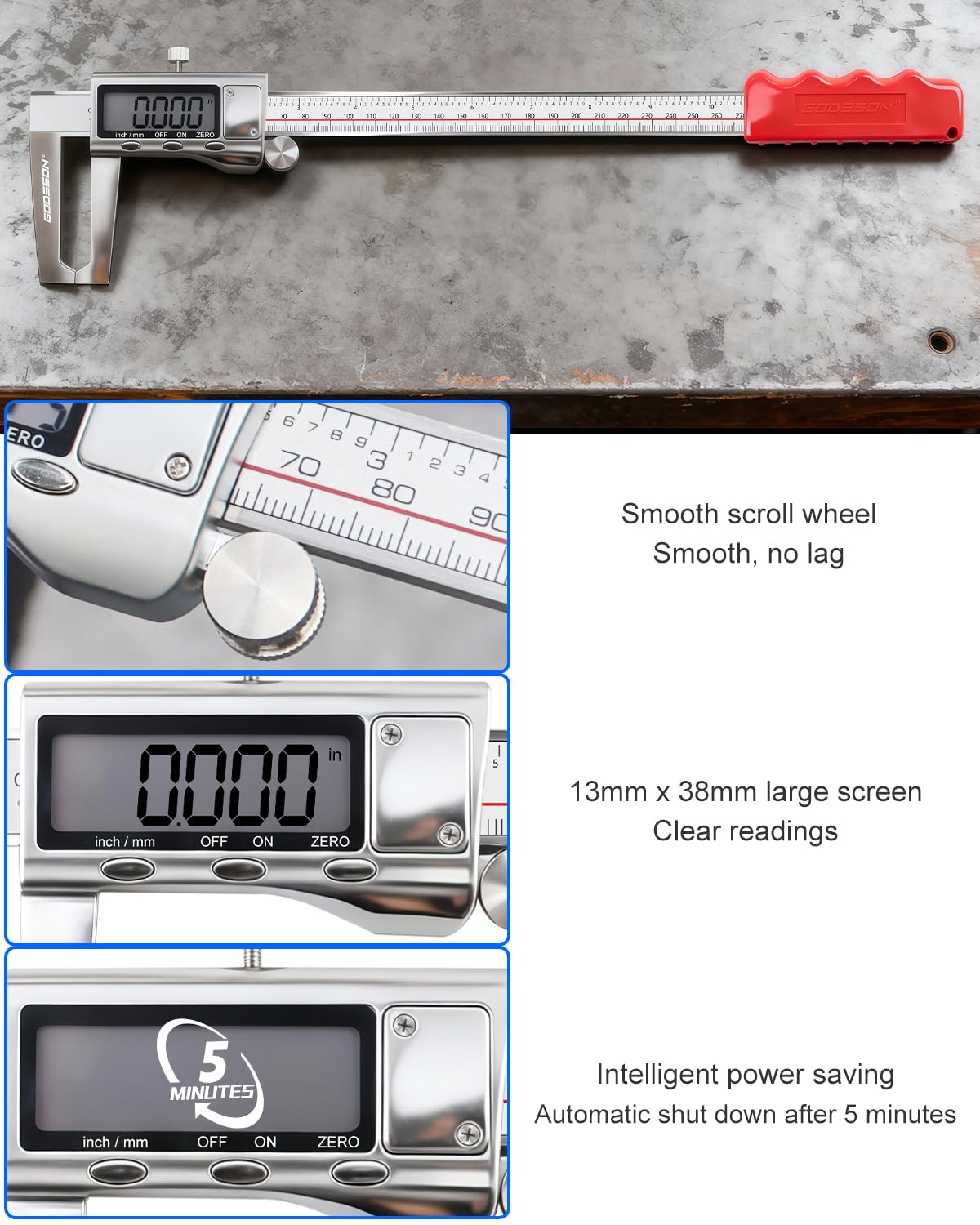

3. Digital Type Tread Depth Gauge

The digital tread gauge provides a precise electronic reading with decimal-point accuracy and multi-unit display (mm/inch). It suits those who want clarity, memory, and consistency in measuring tires across multiple vehicle types.

Key Advantages:

-

High-resolution digital display

-

Switchable units (mm/inch)

-

Battery included

-

Compact and lightweight

Use Case Example:

An auto detailing shop wants to bundle a “full tire health report” into its premium package. Technicians use the digital gauge to measure tread wear down to the decimal, offering customers visual proof with printed results.

ATSAFEPRO Makes It Easy to Measure Tire Safety

Not all tire tread gauges are equal. Depending on who you are and how you use it, the right tool could be analog, color-based, or digital. Here’s a quick summary to guide your choice:

| Product Type | Best For | Key Benefit |

|---|---|---|

| Dial Tread Depth Gauge | Professionals, workshops | Precision without batteries |

| Color Coded Tread Gauge | Fleets, casual drivers | Instant visual feedback |

| Digital Tread Depth Gauge | Technicians, detailed reporting | High-accuracy readout |

ATSAFEPRO provides all three options—each tested for accuracy, usability, and durability.

Frequently Asked Questions

Q1: How deep should tire tread be?

Most tires start with 8–10 mm tread. Replace them when they reach 2 mm (legal minimum in most countries is 1.6 mm).

Q2: Are digital tread gauges more accurate?

Yes. They provide decimal-level precision and reduce human error in reading scales.

Q3: Can I use the same tread gauge on cars and motorcycles?

Yes. All ATSAFEPRO tread gauges are compatible with car, SUV, bike, and truck tires.

Choose Your Tire Tread Gauge with Confidence

Whether you're a fleet safety manager or just checking your own tires at home, choosing the right tire tread depth gauge improves safety, reduces wear, and helps avoid costly surprises. ATSAFEPRO offers reliable options for every user—from dial type tread gauges for professionals to color-coded tools for fast visual checks.

Explore all options on our homepage or contact us for help choosing the perfect fit