How to choose the right tire pressure gauge for accurate pressure check

Tire pressure not only affects vehicle performance, but also affects driving safety. Whether you are a daily commuter, self-driving traveler or fleet manager, the right oneTire pressure gaugeAll can help you detect tire pressure drops early, save fuel, and extend tire life.

Different requirements, different solutions

There is no universal standard. Let's analyze the different user types and how the ATSAFEPRO solution meets their needs:

1.Daily driving

You need reliable and easy-to-read meter. with backlit displayDigital tire pressure gaugeIt is perfect for daily use at home and can be easily used even in low light.

recommend:ATSAFEPRO D40 Digital Pressure Gauge - Fast, Backlit, Dual Unit (PSI/bar)

2.Workshop technicians/professionals

Accuracy and calibration are crucial if you need to deal with a large number of vehicles or different types of vehicles. Please select CalibratedAnd no battery requiredMechanical tire pressure gauge.

recommend:ATSAFEPRO ProDial Gauge – impact resistance, ISO calibration

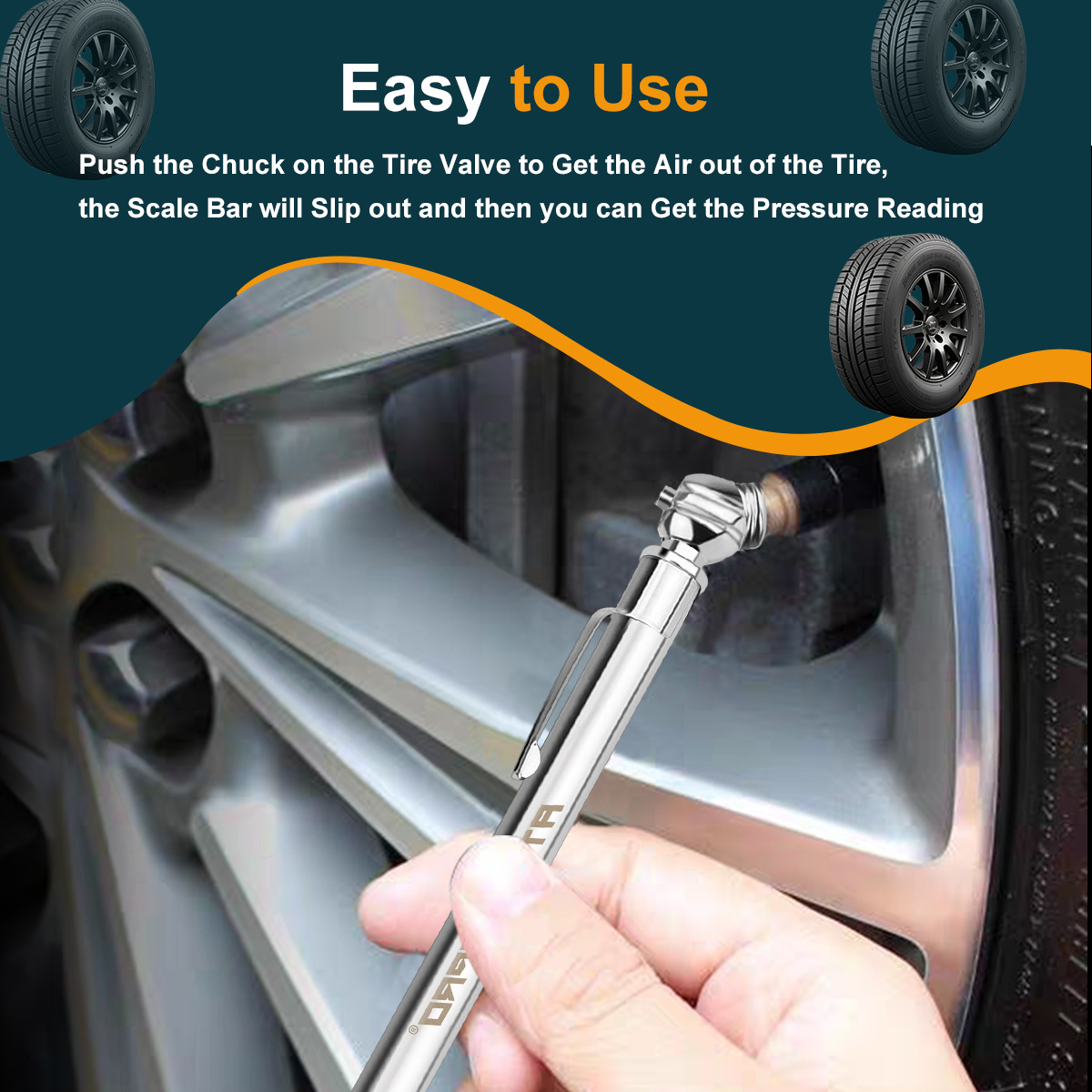

3.Emergency use or backup

Need a tool that can be used anywhere, no battery or screen required?Pencil-type tire pressure gaugeSmall, sturdy and ready to use.

recommend:ATSAFEPRO Classic Pencil Gauge – Simple, reliable, suitable for placing in glove box

4.Bicycle and motorcycle owners

In the low PSI range, accuracy is crucial. Please use a dedicated low-pressure digital or mechanical pressure gauge designed for small tires.

recommend:ATSAFEPRO BikePro Gauge – Fine calibration of two-wheelers

What should you pay attention to when purchasing a high-quality tire pressure gauge

Choosing the right air pressure tool doesn’t just mean checking the price:

-

Accuracy: Seek ±2–3% PSI tolerance

-

calibration: It is best to be ANSI/ISO certified

-

Durability: Steel shell or rubber protective cover can withstand drops

-

PSI Range: Make sure it meets your tire specifications (for example, 0-100 PSI for cars and 0-160 PSI for trucks)

-

show: Digital and analog – choose the easiest way to read

All ATSAFEPRO instruments are strictly tested and designed for professional and personal use.

Compatible tools and add-ons

Tire pressurecountJust the beginning. For optimal tire maintenance, consider using the following tools:

-

With automatic shutdown functionInflatable pressure tool

-

Tread depth gaugeUsed to monitor wear

-

With integrated digital instrumentationAir compressor

With the right combination, you can create a complete tire maintenance system for your vehicle.

FAQ

Question 1: How often should I check the tire pressure?

Check it at least once a month and also before long-distance travel. When temperatures plummet or loads are too heavy, inspections may be required.

Question 2: Does the digital tire pressure gauge need to be recalibrated?

Not common, but may require recalibration if dropped or exposed to extreme heat. All ATSAFEPRO digital instruments are precalibrated.

Question 3: Can I use the same tire pressure gauge for my bike and truck?

This depends on the air pressure range. Motorcycles use low-range air pressure gauge (0-60 PSI) and trucks use high-range air pressure gauge (0-160 PSI).

Invest in the right tire tool – drive safer and smarter

Choosing a suitable tire pressure gauge is not about the appearance and function, but about choosing the right tools according to actual needs. ATSAFEPRO offers digital tire pressure gauge, pencil tire pressure gauge and mechanical tire pressure gauge to meet the needs of DIY enthusiasts, professionals and everyday drivers.

On the ATSAFEPRO homepageExplore our full range of air pressure tools,orContact Us Herefor personalized suggestions.