Global Standards in Accuracy: How Precision Pressure Gauge Exporters Support Industrial Safety

Pressure Control: The Overlooked Foundation of System Reliability

In modern industrial systems, pressure management directly impacts safety, efficiency, and product quality. Yet, many operations still rely on inconsistent, locally sourced gauges without calibration traceability.

The result? Subtle pressure errors accumulate — leading to pump strain, energy waste, and component fatigue. According to the International Society of Automation (ISA), miscalibrated pressure instruments contribute to 25% of unplanned maintenance incidents in process facilities.

That’s why global exporters like ATSAFEPRO focus on precision-built gauges designed for repeatable accuracy and international compliance across industries.

Engineering Principles Behind Precision Gauges

ATSAFEPRO’s precision pressure gauges combine CNC-machined housings, temperature-compensated diaphragms, and laser-calibrated sensors. Each model is tested under variable load and vibration to maintain consistency within ±1% of full-scale accuracy.

Core design features include:

-

Dual-scale indicators (PSI/bar) for cross-market compatibility

-

Bourdon tube or piezoresistive sensor architecture

-

Anti-corrosive stainless-steel casings for chemical and hydraulic environments

-

Shock-absorbing glycerin fill to stabilize readings in high-vibration conditions

These design principles ensure reliable measurement across pressure ranges from 0–10,000 PSI, critical for automotive service stations, oil refineries, and pneumatic assembly lines.

| Specification | Conventional Gauge | ATSAFEPRO Precision Gauge |

|---|---|---|

| Accuracy | ±3% | ±1% or better |

| Housing Material | Aluminum | 304/316 Stainless Steel |

| Calibration Traceability | None | ISO/IEC 17025 |

| Temperature Stability | Poor | ±0.5% drift |

| Service Life | 1 year | 5+ years |

Data verified through ATSAFEPRO’s internal QC reports, 2025.

Technical Superiority and Export-Grade Reliability

Exporting precision tools demands more than good hardware — it requires traceable calibration certificates, conformity with CE/RoHS, and global service support. ATSAFEPRO meets all of these through:

-

ISO 9001:2015 quality management for consistent production

-

Automated sensor calibration traceable to NIST and EU standards

-

Regional testing compliance for EU, North America, and ASEAN markets

Digital models further integrate real-time error detection algorithms, providing consistent readings under high temperature or fluid vibration — a critical advantage for international clients maintaining safety across diverse operating environments.

Field Applications Across Industries

Precision pressure gauges are indispensable in industrial systems that depend on constant pressure regulation. ATSAFEPRO’s clients span:

-

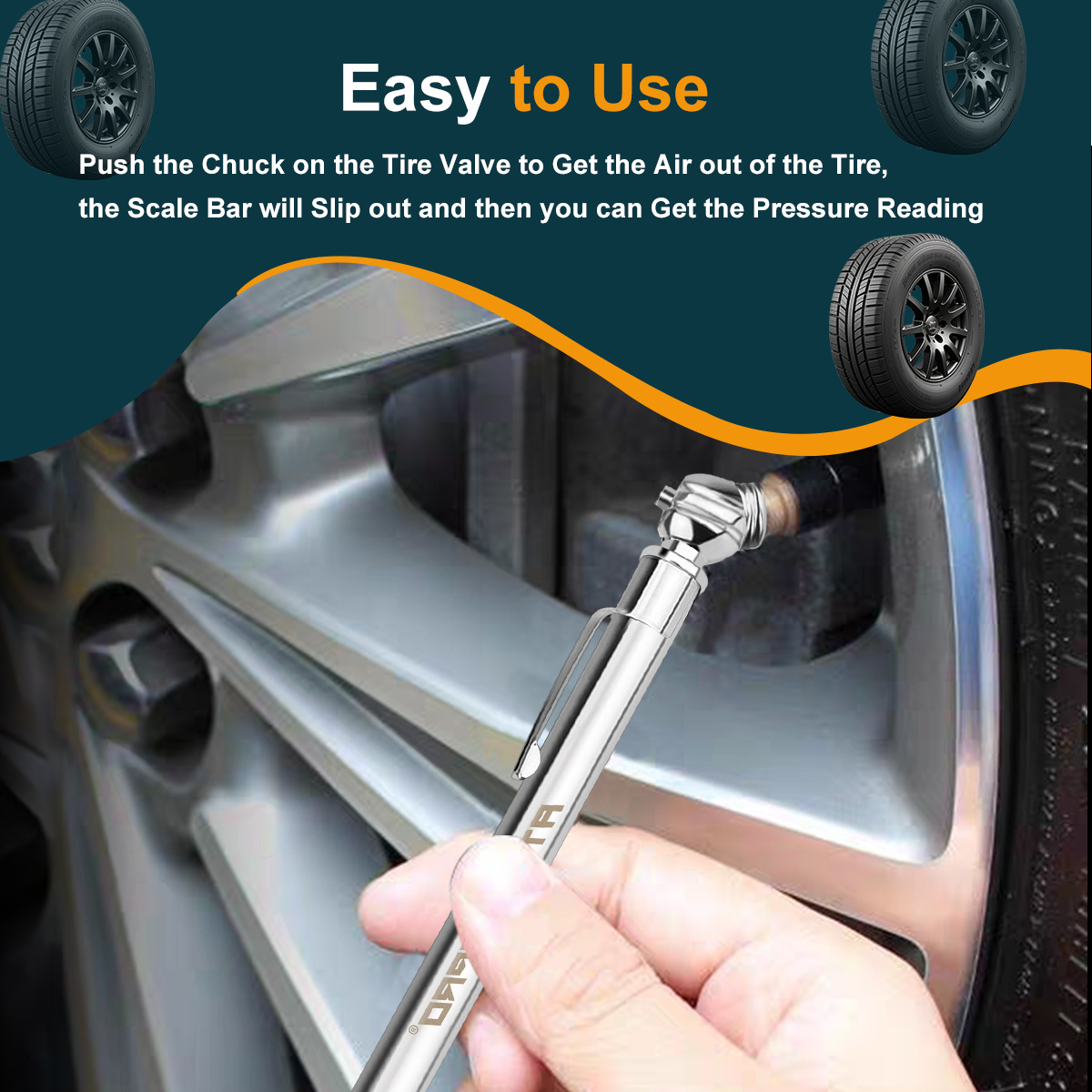

Automotive Maintenance: Tire inflation, hydraulic brake systems, and fuel line diagnostics

-

Manufacturing Plants: Compressed air monitoring and pneumatic control lines

-

Energy & Oil Sectors: Pipeline integrity checks under variable pressure

-

HVAC Systems: Air duct calibration and leak prevention

A case study from a Thai automotive OEM showed that switching to ATSAFEPRO’s digital pressure gauges reduced calibration downtime by 32% and improved service accuracy across multiple workshops.

Guidance for Selecting the Right Pressure Gauge

When choosing a precision gauge, buyers should evaluate:

-

Pressure range compatibility: Ensure it covers 75–100% of the system’s normal operating pressure.

-

Accuracy requirements: For laboratory or calibration-grade applications, ±0.25% F.S. is recommended.

-

Environmental resistance: Select glycerin-filled stainless models for high-vibration or temperature-exposed environments.

-

Maintenance availability: Choose exporters with calibration support and replacement parts.

ATSAFEPRO provides tailored solutions with digital, mechanical, and compound pressure gauge options designed to suit different industrial segments.

Expert Answers to Buyer Concerns

Q1: What’s the difference between digital and mechanical precision gauges?

Digital gauges offer data logging and faster response, while mechanical models excel in durability and extreme temperature tolerance.

Q2: How often should gauges be recalibrated?

Typically every 12 months or after 10,000 pressure cycles.

Q3: Can ATSAFEPRO export to regions with special certification standards?

Yes — all gauges meet CE, RoHS, and ISO 17025 calibration traceability for international shipment.

Q4: Do your gauges support OEM customization?

Yes. Logo engraving, dial modification, and pressure range adjustments are available for bulk orders.

Building Long-Term Trust Through Certified Precision

Industrial safety depends on reliable measurement — and precision pressure gauges are its backbone.

ATSAFEPRO’s commitment to export-grade quality, traceable calibration, and long-term support ensures every system operates safely and efficiently, wherever it’s installed.

Discover the complete range of certified pressure measurement tools on our ATSAFEPRO Homepage or contact our technical sales team directly via Contact Us.