Understanding the Challenges with Pneumatic Air Chucks

In the world of manufacturing and mechanical operations, pneumatic air chucks play a crucial role in securing workpieces during machining processes. However, users often encounter significant issues with pneumatic air chucks, such as inconsistent gripping pressure, air leakage, and premature wear, which can lead to production delays and increased costs. For instance, air chuck systems that fail to maintain steady pressure might cause workpieces to slip, resulting in defective products and safety hazards in workshops. These problems are exacerbated in high-demand environments where efficiency is key, making it essential to address these inefficiencies to maintain productivity and quality.

Exploring Common Problems in Air Chuck Systems

Delving deeper, one of the primary issues with air chuck is the inefficiency in pressure control, which can cause energy wastage and reduce the lifespan of the equipment. Air chucks, particularly those not designed with advanced features, often suffer from rapid air loss during operation, leading to inconsistent performance and the need for frequent maintenance. Additionally, locking air chuck mechanisms might fail under heavy loads, compromising the stability of the workpiece and increasing the risk of accidents. This not only affects daily operations in mechanical workshops but also adds to operational expenses through downtime and replacement parts. The root of these problems lies in outdated designs that don't optimize air flow, highlighting the need for innovative solutions to enhance reliability and reduce long-term costs.

Solutions for Enhancing Pneumatic Air Chuck Performance

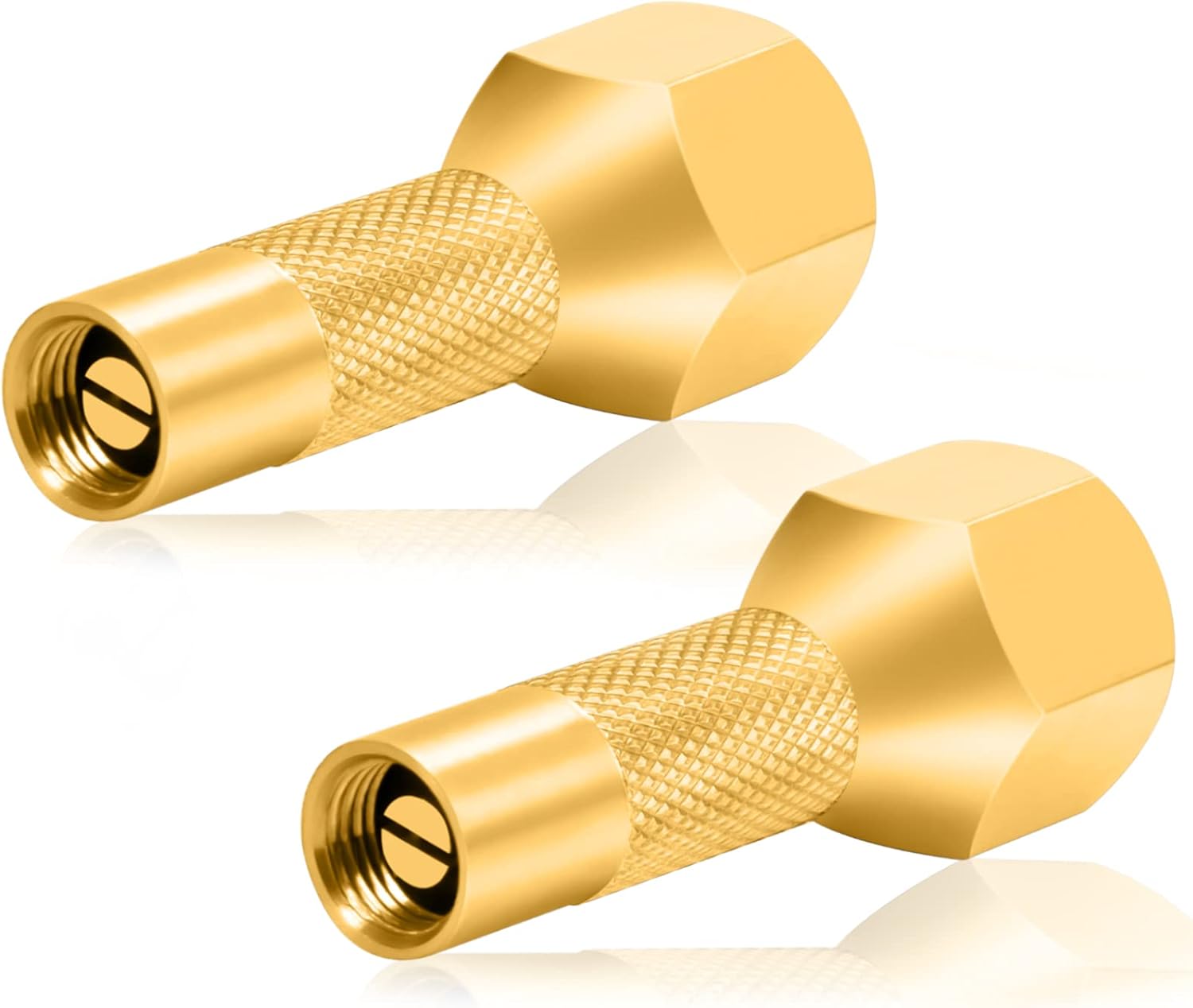

To combat the challenges associated with pneumatic air chucks, implementing advanced technologies like our innovative Closed Flow Air Valve offers a practical and effective solution. This valve, engineered with robust brass construction, ensures superior pressure control by only releasing air when necessary, thereby minimizing air loss and optimizing the efficiency of air chuck systems. For users dealing with locking air chuck issues, integrating this valve can provide a tighter seal and more reliable locking mechanisms, preventing slippage and extending the life of your equipment. By adopting such state-of-the-art engineering, businesses can achieve consistent results with minimal maintenance, whether in a bustling mechanical workshop or a home garage setup. This approach not only conserves energy and reduces costs but also enhances overall safety and productivity, making your operations smoother and more efficient.

Realizing Long-Term Benefits and Best Practices

Beyond immediate problem-solving, the adoption of solutions like the Closed Flow Air Valve brings long-term benefits to pneumatic air chuck users, including improved durability and reduced environmental impact through energy conservation. For example, by ensuring that air chuck systems operate at peak efficiency, companies can lower their carbon footprint while maintaining high standards of precision in manufacturing. Best practices involve regular inspections and pairing these valves with compatible locking air chuck components to maximize performance. Ultimately, this problem-solution strategy empowers users to overcome common pitfalls, fostering a more reliable and cost-effective workflow that supports business growth and innovation in the industry.