Maintaining Torque Accuracy: A Step-by-Step Calibration Guide

Why Calibration Isn’t Optional in Professional Service

Picture this: a fleet truck returns after brake service, but a caliper bolt works loose within a week. The tech swears they hit the torque spec — but the wrench was last calibrated two years ago. In another workshop, a head gasket job fails because over-torqued bolts warped the cylinder head, costing hours in rework.

A calibrated torque wrench isn’t just a tool, it’s proof that every fastening meets OEM and industry standards like ISO 6789 or ASME B107. Regular calibration prevents costly rework, warranty claims, and — most importantly — safety risks.

How Often Should a Torque Wrench Be Calibrated?

-

Professional use: Every 12 months or 5,000 cycles, whichever comes first.

-

After overload: If the wrench has been used beyond its rated capacity.

-

After impact: If dropped or subjected to shock.

-

Before critical audits: QA inspections in regulated industries require documented proof of accuracy.

Step-by-Step: How to Calibrate a Torque Wrench

Using a Torque Wrench Calibration Tool

-

Secure the Tool — Mount the torque wrench in the calibration rig per manufacturer’s instructions.

-

Set a Test Value — Choose a torque value within the wrench’s most common operating range (20–80% of capacity).

-

Apply Torque — Slowly pull until the wrench signals (click or digital alert).

-

Read Deviation — Compare the indicated torque to the calibration tool’s measurement.

-

Adjust if Possible — Some wrenches have an internal adjustment mechanism; others require professional service.

-

Repeat Across Ranges — Verify at low, mid, and high torque points.

Without a Calibration Tool (Verification Only)

-

Use a certified torque tester at a parts supplier or calibration shop.

-

Record all results for workshop compliance logs.

Real-World Scenarios Where Calibration Saves the Job

-

Fleet Depot

Heavy trucks have wheel nuts torqued daily to 650 Nm. Just a 5% accuracy drift can mean the difference between secure loads and dangerous wheel-offs on the highway. Regular calibration catches this before it becomes a roadside emergency. -

Industrial Plant Assembly

Assembly line torque checks fail when tools drift outside ISO tolerance. Unplanned downtime costs thousands per hour — recalibrated wrenches keep production running and QA audits clear. -

Motorcycle Workshop

Fine-thread bolts on aluminum components are stripped when a low-range torque wrench reads high. A calibration reset restores precision and saves on costly replacement parts. -

Professional Bicycle Service

Carbon fiber seatposts and stems require 4–6 Nm. An uncalibrated low-range wrench applying even 1 Nm too much can crush parts worth hundreds of dollars. Routine calibration ensures safe clamping force and protects expensive components. -

Home Bicycle Maintenance

Enthusiasts servicing road or mountain bikes at home often rely on a single torque wrench for all jobs. Without periodic checks, even minor drift can cause loose handlebars or over-compressed headset bearings — both of which compromise ride safety. -

DIY Vehicle Projects

Home mechanics replacing brake calipers or performing engine work risk either under-tightening (leading to brake failure) or over-tightening (damaging threads) if their torque wrench isn’t accurate. A quick check with a torque wrench calibration tool ensures confidence before reassembly.

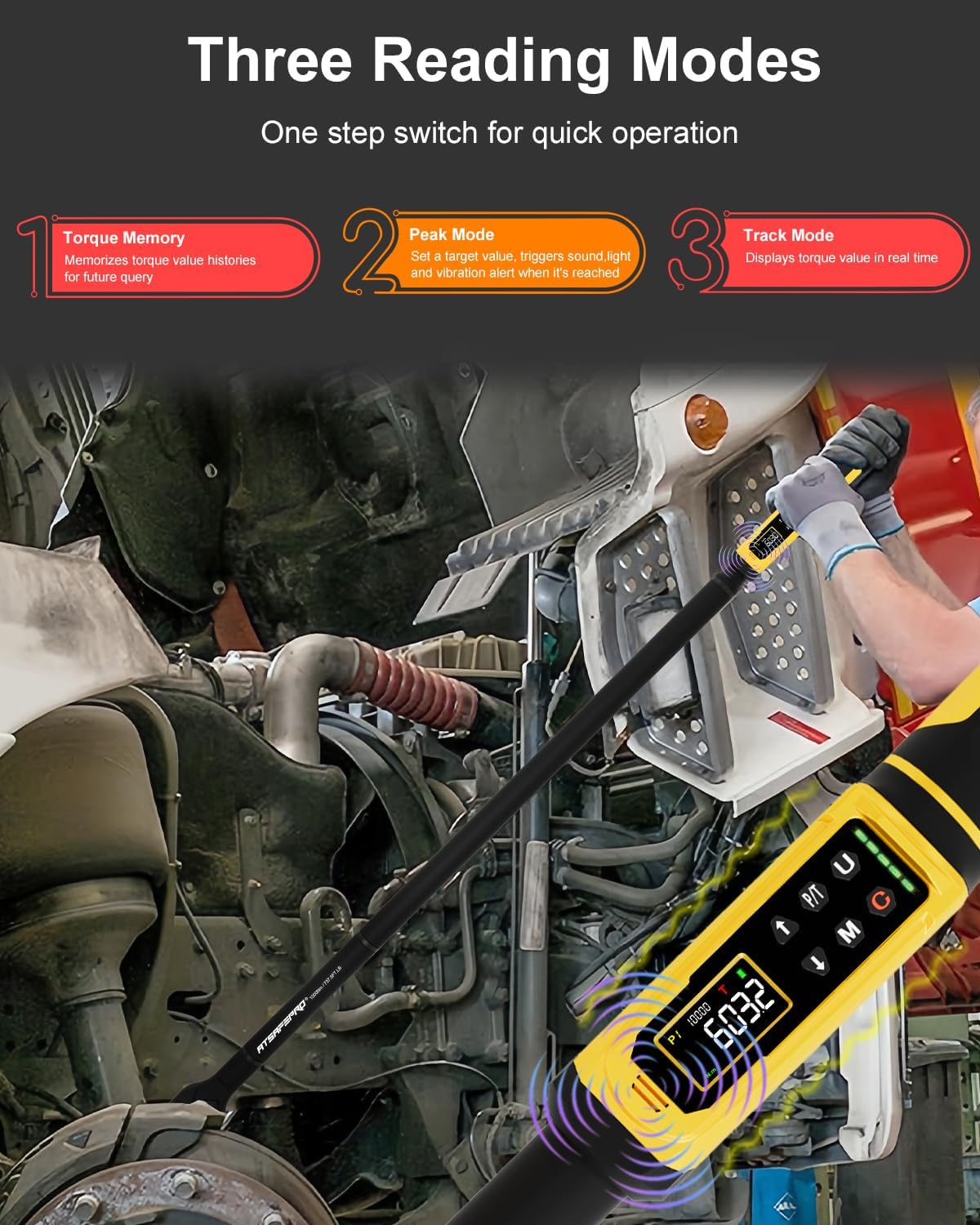

Why an ATSAFEPRO Calibrated Torque Wrench is the Better Starting Point

Buying a calibrated torque wrench means it’s ready for precise work from the first use — with a traceable ISO 6789 calibration certificate included. ATSAFEPRO models are engineered for slower calibration drift, meaning less downtime between service intervals.

For workshops that manage their own tools, pairing wrenches with an ATSAFEPRO torque wrench calibration tool allows in-house checks, so you’re never guessing about accuracy before a critical job.

Key Takeaways for Professionals

-

Calibration is a planned maintenance task, not a reaction to failure.

-

Keep a calibration log for each wrench in your workshop or fleet kit.

-

Train staff on correct torque application to extend calibration stability.

-

Invest in a torque wrench set and calibration tool to standardize accuracy across all jobs.

For a full range of calibrated torque wrenches and professional calibration tools, visit the ATSAFEPRO product page or check our homepage for workshop solutions. For service scheduling or bulk tool calibration programs, contact us today.