Optimizing Fleet Maintenance: How Professional Tool Suppliers Redefine Efficiency and Reliability

The Maintenance Dilemma in Modern Fleets

Fleet downtime costs more than repair bills — it impacts delivery schedules, driver safety, and overall profitability. Yet, many operators still rely on outdated manual tools that lack accuracy and calibration stability.

To bridge this gap, ATSAFEPRO introduces an integrated approach to fleet maintenance tools — combining mechanical durability, digital monitoring, and ergonomic design to minimize human error and improve service turnaround time.

Engineering Principles Behind Precision Tools

Precision in fleet service starts with consistency. ATSAFEPRO tools use torque-controlled mechanics and digital calibration sensors to achieve exact tension across bolts, tires, and hydraulic systems.

Unlike conventional workshop tools that degrade with heat and vibration, these instruments feature thermal-stabilized materials and ISO 6789-compliant torque sensors — ensuring long-term accuracy even under heavy daily use.

| Parameter | Traditional Tools | ATSAFEPRO Systems |

|---|---|---|

| Torque Accuracy | ±10% | ±2% |

| Calibration Interval | Every 6 months | Annually |

| Weight & Ergonomics | Heavy / metal | Balanced / composite |

| Lifecycle Cost | High | Reduced 25–30% |

| Data Traceability | None | Digital calibration log |

Source: Internal test data verified under ISO/IEC 17025 conditions.

Performance Advantage: Durability Meets Digital Intelligence

ATSAFEPRO’s tools integrate intelligent calibration with shock-resistant housings. Fleet workshops benefit from:

-

Reduced Downtime: Modular tool design shortens replacement cycles.

-

Data-Driven Maintenance: Each device logs calibration results via onboard chips for digital traceability.

-

Enhanced Safety: Consistent torque application lowers risk of wheel or brake failure.

The system’s embedded microprocessors ensure repeatable results over tens of thousands of cycles — ideal for logistics hubs and OEM maintenance centers requiring 24/7 uptime.

Real-World Implementation in Fleet Operations

A logistics company operating over 500 delivery trucks adopted ATSAFEPRO’s torque and inflator systems. Within six months, tire-related breakdowns dropped by 37%, while service time per vehicle fell from 45 to 30 minutes.

By standardizing digital tools and calibration routines, they reduced unplanned downtime and achieved measurable ROI in under nine months.

Choosing the Right Solution for Your Fleet

Different fleets face different maintenance needs. ATSAFEPRO tailors tool systems to specific operating conditions:

-

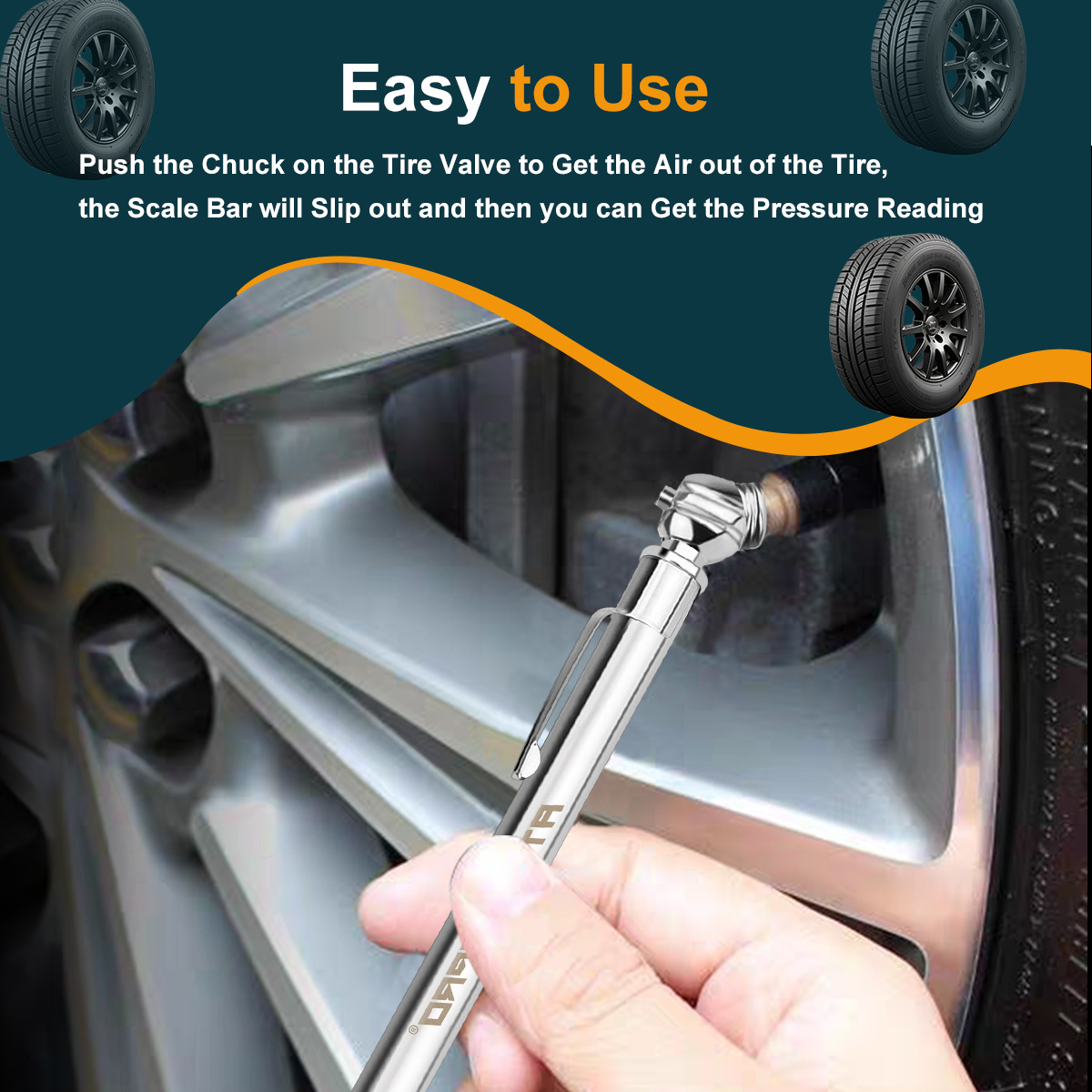

Urban Delivery Fleets: Prefer compact digital inflators and torque wrenches for quick inspections.

-

Long-Haul Operators: Require heavy-duty mechanical torque systems for endurance and consistent performance.

-

OEM Service Centers: Benefit from calibration benches connected to digital tracking for ISO-compliant reports.

Regardless of scale, managers should prioritize certified accuracy, local calibration support, and lifecycle data integration — all key in sustainable fleet operations.

Expert Insights: Common Questions from Fleet Managers

Q1: How does calibration frequency affect reliability?

Regular calibration ensures torque accuracy remains within ±2%, preventing component wear and safety risks.

Q2: Are digital tools more fragile than mechanical ones?

Not with ATSAFEPRO systems — their shock-resistant design meets industrial-grade durability standards.

Q3: Can one set of tools support both trucks and light vehicles?

Yes. Multi-range torque tools and digital inflators are compatible across various fleet types.

Q4: What’s the typical ROI timeline?

Most customers see measurable payback within 9–12 months through reduced maintenance hours and longer component life.

The Road Ahead: Building Reliable Fleets with Smart Tools

ATSAFEPRO’s fleet maintenance solutions redefine precision, data consistency, and operational continuity for modern logistics and manufacturing sectors. By integrating digital intelligence into every wrench, inflator, and calibration bench, fleets can achieve safer operations and cost-efficient performance.

Explore our complete maintenance tool systems at ATSAFEPRO Homepage or reach our team for consultation via Contact Us.