Understanding the Fundamentals of Digital Calipers

The digital caliper stands as a cornerstone in precision measurement tools, revolutionizing how engineers, machinists, and technicians quantify dimensions with unparalleled accuracy. At its core, a digital caliper is an electronic device that uses a linear encoder to convert physical measurements into digital readings displayed on an LCD screen. Unlike traditional vernier calipers, which rely on manual alignment and visual interpolation, the digital caliper eliminates human error through automated readout, offering resolutions as fine as 0.01mm or 0.0005 inches. This precision is achieved via a capacitive or inductive sensor that detects the position of the sliding jaw relative to the main scale, translating it into numerical data instantly.

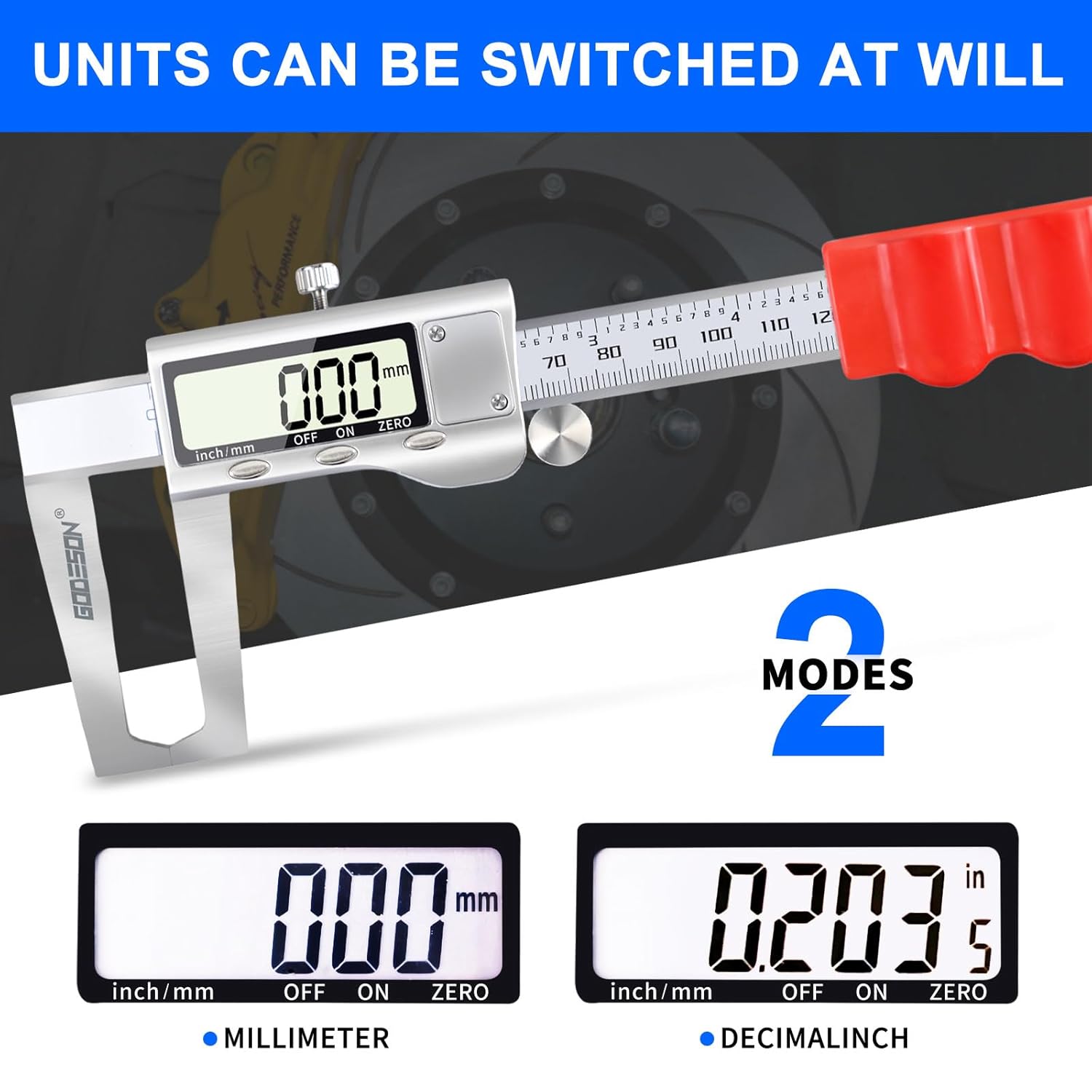

In technical applications, the digital caliper's ability to switch between metric and imperial units—often with a single button press—enhances its versatility. For instance, in manufacturing, where tolerances can be as tight as microns, the tool's zero-setting function allows for relative measurements from any reference point, ensuring consistency across multiple parts. Battery-powered operation, typically with a CR2032 lithium cell, provides portability without sacrificing reliability, making it indispensable in field inspections or assembly lines. However, selecting the right digital caliper involves considering factors like jaw depth, which determines internal and external measurement capabilities, and the overall build quality to withstand industrial rigors.

Delving into GODESON Digital Caliper Features

The GODESON digital caliper exemplifies advanced engineering tailored for demanding environments, particularly through its IP54 waterproof rating that shields against water splashes, oil, and dust ingress. This protection is crucial in workshops where contaminants are commonplace, preventing internal components from corrosion or failure. Constructed from hardened stainless steel, the GODESON digital caliper offers a robust frame that resists wear while maintaining dimensional stability, with measuring jaws honed to razor-sharp edges for superior contact and minimal measurement deviation.

Key to its functionality is the large LCD display, which not only shows absolute measurements but also supports unit conversion between millimeters and inches, alongside a fractional mode for applications requiring imperial fractions like 1/16th or 1/32nd. The ergonomic design includes thumb rollers for smooth jaw movement and locking screws to secure readings, reducing operator fatigue during prolonged use. Powered by a long-lasting battery, the GODESON digital caliper ensures uninterrupted performance, with an auto-off feature after inactivity to conserve energy. Its depth rod extension further broadens utility for stepped or recessed measurements, making it a go-to for automotive repair, aerospace prototyping, and quality control in electronics assembly.

From a technical standpoint, the GODESON digital caliper's accuracy is validated through calibration standards traceable to NIST or equivalent bodies, boasting a linearity error of under 0.02mm across its 150mm or 200mm measuring range. This level of precision supports statistical process control (SPC) integration, where data output via optional USB interfaces allows direct logging into software for analysis, streamlining compliance with ISO 9001 standards in manufacturing.

Exploring GODESON Caliper Specifications in Depth

GODESON caliper specifications highlight a blend of durability and innovation, starting with the IP54 ingress protection that complies with IEC 60529 standards, ensuring the tool operates flawlessly in non-submersible wet conditions up to 1 meter of water for brief exposures. The stainless steel components undergo heat treatment to achieve a hardness of HRC 55-60, providing resistance to deformation under repeated clamping forces, while the LCD's anti-glare coating enhances readability in varying lighting, from bright shop floors to dimly lit inspection areas.

Detailed specs include a display resolution of 0.01mm/0.0005", with absolute accuracy of ±0.03mm for models up to 200mm span, and repeatability within ±0.01mm, making it suitable for high-precision tasks like gauging gear teeth or verifying PCB component leads. The jaw configurations—external, internal, and step types—span widths up to 40mm for external and 20mm for internal measurements, complemented by a 10mm depth bar for probing holes or grooves. Battery life exceeds 12,000 hours of continuous use, and the device's weight, around 150g, facilitates one-handed operation without compromising stability.

Furthermore, GODESON caliper specifications incorporate user-centric features like absolute and incremental modes, allowing measurements from fixed zeros or relative offsets, which is vital in coordinate measuring machine (CMM) setups. Environmental tolerances extend to operating temperatures from 0°C to 40°C and humidity up to 80% non-condensing, underscoring its suitability for diverse industrial climates. Compared to competitors, the GODESON model stands out for its corrosion-resistant finish, achieved via electropolishing, which reduces surface adhesion of particulates and extends service life beyond 5 years under normal use.

Practical Applications and Maintenance of Digital Calipers

In practical terms, the digital caliper, especially models like the GODESON variant, finds extensive use in mechanical engineering for tasks such as dimensioning shafts, bores, and threads with sub-millimeter fidelity. In quality assurance labs, it pairs with go/no-go gauges to verify part conformance, while in education, it teaches metrology principles through hands-on measurement exercises. For hobbyists crafting custom fixtures or model parts, the tool's fractional readout simplifies conversions, bridging professional and amateur divides.

Maintenance of the GODESON digital caliper involves periodic cleaning with isopropyl alcohol to remove residues, avoiding ultrasonic baths that could damage the electronics. Calibration should occur annually or after 10,000 cycles, using certified gauge blocks to reset the zero point and verify span accuracy. Storing in a protective case away from magnetic fields prevents sensor drift, ensuring longevity. Troubleshooting common issues, like erratic readings, often traces to battery depletion or jaw misalignment, resolvable by simple resets or lubrication with light machine oil on sliding surfaces.

Advancements in digital caliper technology, as seen in GODESON caliper specifications, include Bluetooth connectivity for wireless data transfer, enhancing integration with Industry 4.0 workflows. This evolution not only boosts efficiency but also reduces transcription errors in data-heavy environments. For professionals seeking reliability, investing in a GODESON digital caliper means embracing a tool that aligns precision with practicality, ultimately elevating project outcomes across technical disciplines.

Overall, the digital caliper's role in modern metrology cannot be overstated, with the GODESON model setting benchmarks in waterproofing, accuracy, and user interface. By adhering to these specifications, users can achieve measurements that drive innovation and quality in engineering endeavors.