Discover the Precision of the ATsafepro Torque Wrench

When it comes to achieving perfect torque in mechanical tasks, the ATsafepro Torque wrench stands out as an essential tool for both professionals and hobbyists. This multifunctional device ensures that every bolt and nut is tightened to the exact specifications required, preventing damage from over-tightening or under-tightening. With its innovative design and reliable performance, the ATsafepro Torque wrench has become a favorite among mechanics who prioritize accuracy in their work.

Understanding the ATsafepro Torque Wrench

The ATsafepro Torque wrench is engineered for versatility and durability, featuring a sleek red finish that not only looks professional but also resists corrosion over time. Its adjustable torque settings allow users to dial in precise measurements, typically ranging from low to high foot-pounds, making it suitable for a wide array of applications. Whether you're assembling furniture, working on automotive repairs, or maintaining heavy machinery, this tool provides the control needed to get the job done right. The inclusion of an extension bar and socket adapter, both constructed from high-strength chrome vanadium, adds to its practicality by enabling access to confined spaces without compromising on torque accuracy. Packed in a robust carrying case, the ATsafepro Torque wrench is designed for easy transport and storage, keeping it protected from the elements and ready for immediate use.

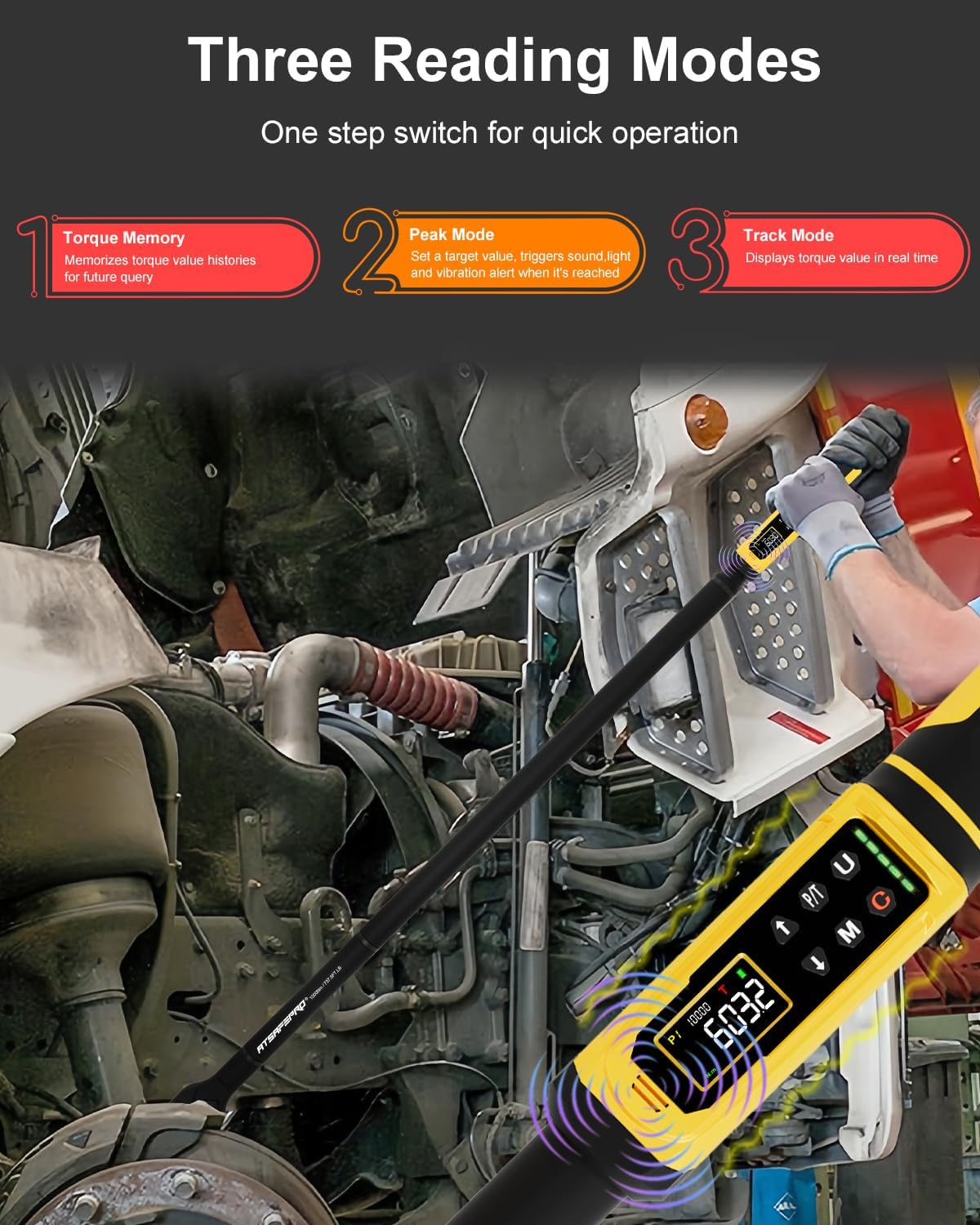

Digital Torque Wrench: Modern Precision at Your Fingertips

For those seeking advanced features, the digital torque wrench variant within the ATsafepro lineup elevates the standard model with electronic displays and real-time feedback. A digital torque wrench offers audible alerts and visual indicators when the desired torque level is reached, reducing the guesswork associated with manual adjustments. This technology is particularly beneficial in high-stakes environments like aviation or automotive assembly lines, where even minor deviations can lead to significant issues. The ATsafepro digital torque wrench integrates seamlessly with its mechanical counterparts, providing options for users who prefer tech-driven tools. Battery-powered for convenience, it ensures consistent performance without the need for constant recalibration, and its memory function allows for tracking multiple torque settings during a single project. Compared to traditional models, the digital torque wrench minimizes human error, making it an indispensable asset for precision-oriented tasks.

Mechanical Torque Wrench: Reliable and Time-Tested

On the other hand, the mechanical torque wrench option from ATsafepro delivers straightforward reliability without relying on electronics, appealing to users who value simplicity and robustness. This type features a classic click mechanism that signals when the preset torque is achieved, offering tactile feedback that's easy to interpret even in noisy workshops. The ATsafepro mechanical torque wrench is built to withstand rigorous daily use, with its chrome vanadium components ensuring longevity under heavy loads. Ideal for DIY enthusiasts tackling home repairs or mechanics handling routine maintenance, it provides consistent results across various torque ranges. Unlike digital models, the mechanical torque wrench requires no batteries, making it a dependable choice for fieldwork where power sources might be limited. Its calibration is user-friendly, often including a detailed manual that guides proper setup and maintenance to preserve accuracy over years of service.

Comparing Digital and Mechanical Options in the ATsafepro Line

Choosing between a digital torque wrench and a mechanical torque wrench often depends on the specific demands of your projects. The ATsafepro Torque wrench bridges these worlds by offering both in its multifunctional series, allowing users to select based on preference. Digital versions excel in environments requiring data logging and precise measurements, such as quality control in manufacturing, where records of torque applications can be vital for compliance. Mechanical models, however, shine in scenarios demanding durability and minimal maintenance, like outdoor construction sites or mobile repair services. Both types incorporate the same high-quality materials, ensuring that the ATsafepro Torque wrench maintains its reputation for precision regardless of the chosen format. Factors like cost, ease of use, and environmental conditions play a role in the decision, but ATsafepro's commitment to quality means either option will deliver exceptional performance.

Applications and Benefits of the ATsafepro Torque Wrench

The versatility of the ATsafepro Torque wrench extends to numerous applications, from automotive wheel lug nuts to bicycle assembly and even aerospace components. In the automotive sector, using a proper torque wrench prevents issues like warped brake rotors or stripped threads, enhancing vehicle safety and longevity. For DIY projects, it empowers homeowners to undertake complex tasks with confidence, knowing their work meets professional standards. The tool's ergonomic handle reduces fatigue during extended use, while its accurate calibration—often certified to industry standards—builds trust in every application. Beyond precision, the ATsafepro Torque wrench contributes to efficiency by speeding up workflows; no more second-guessing tightness levels means faster project completion. Environmentally, its durable construction reduces the need for frequent replacements, promoting sustainability in tool usage.

Tips for Maintaining Your ATsafepro Torque Wrench

To maximize the lifespan of your ATsafepro Torque wrench, regular maintenance is key. For digital models, check battery levels periodically and avoid exposure to extreme temperatures that could affect the electronics. Mechanical versions benefit from occasional lubrication of moving parts and storage in the provided case to prevent dust accumulation. Always zero out the torque setting after use to relieve spring tension, preserving calibration accuracy. If precision seems off, professional recalibration services are recommended every 5,000 cycles or annually. By following these practices, users can ensure their digital torque wrench or mechanical torque wrench remains a reliable partner in all endeavors. The ATsafepro Torque wrench's design inherently supports easy upkeep, making it a low-maintenance investment for any toolkit.

Why Choose ATsafepro for Your Torque Needs

In a market flooded with tools, the ATsafepro Torque wrench distinguishes itself through superior engineering and user-focused features. Its combination of style, functionality, and accessibility makes it ideal for novices and experts alike. Whether opting for the digital torque wrench's tech-savvy approach or the mechanical torque wrench's no-fuss reliability, ATsafepro delivers tools that enhance productivity and safety. As demands for precision grow in various industries, investing in an ATsafepro Torque wrench ensures you're equipped for success. With its comprehensive accessories and protective packaging, it's more than just a tool—it's a complete solution for mechanical excellence.