Discovering the Precision of ATSafePro Torque Wrench

The ATSafePro Torque wrench stands out as a premier tool in the world of mechanical precision, offering unmatched accuracy for both professional mechanics and DIY enthusiasts. Engineered with a focus on reliability, this series addresses the core needs of torque application in various settings, from automotive repairs to assembly tasks. Whether you're tightening bolts to exact specifications or ensuring structural integrity, the ATSafePro Torque wrench delivers consistent performance that minimizes errors and enhances safety.

Exploring the ATSafePro Series: Sizes and Specifications

The ATSafePro Torque wrench lineup includes three versatile models tailored to different project scales. The 1/2" Torque Wrench measures 41 cm (16.1 inches) in length and boasts a torque range of 10-170 FT.LB, making it ideal for heavy-duty tasks that require substantial leverage. Its robust build ensures it can handle demanding applications like engine work or suspension repairs without compromising on precision. Moving to the medium-sized option, the 3/8" Torque Wrench, at 30 cm (11.8 inches) long, covers a torque range of 5-50 FT.LB. This model strikes a perfect balance between power and maneuverability, suitable for general automotive maintenance or machinery assembly where space might be limited. For finer work, the 1/4" Torque Wrench, compact at 24 cm (9.4 inches), offers a precise range of 20-240 IN.LB, excelling in delicate operations such as electronics or small engine tuning. Each ATSafePro Torque wrench is crafted with a sleek red finish and an ergonomic black grip, promoting comfortable handling and reducing the risk of slippage during extended use.

Key Features Enhancing Usability and Durability

What sets the ATSafePro Torque wrench apart are its thoughtful design elements that prioritize user experience and longevity. Clear torque scales allow for straightforward adjustments, ensuring you can set and achieve the exact force needed without guesswork. A secure locking mechanism holds your settings firmly in place, preventing accidental changes mid-task and maintaining accuracy throughout the job. The drive head attachments further expand versatility: the 1/2 turn 3/8 drive head, 3/8 turn 1/2 drive head, and 1/4 turn 3/8 drive head all feature a chrome finish that resists corrosion and withstands rigorous use. These components make the ATSafePro Torque wrench adaptable to a wide array of sockets and fasteners, broadening its application in workshops or field repairs.

Comparing Digital and Mechanical Torque Wrenches in the ATSafePro Line

While the ATSafePro series primarily excels in mechanical torque wrenches, it's worth noting how it compares to digital alternatives for those seeking advanced features. A Digital Torque wrench, often equipped with electronic displays and audible alerts, provides real-time feedback that can be invaluable in high-precision environments like aerospace or quality control labs. However, the mechanical ATSafePro Torque wrench offers a dependable, battery-free operation that thrives in rugged conditions where electronics might fail. For instance, the clear analog scales on the ATSafePro models deliver instant visual confirmation, eliminating the need for power sources and reducing downtime. In contrast, a mechanical torque wrench like the ATSafePro emphasizes simplicity and robustness, with its bi-directional calibration ensuring accuracy in both clockwise and counterclockwise directions. Professionals often prefer the mechanical version for its tactile feedback, which allows for intuitive adjustments on the fly.

Advantages of Mechanical Torque Wrenches for Everyday Use

Delving deeper into the mechanical torque wrench category, the ATSafePro Torque wrench exemplifies why this design remains a staple in toolkits worldwide. Unlike digital models that may require calibration checks or software updates, a mechanical torque wrench relies on proven spring-loaded mechanisms that deliver consistent results over time. The ATSafePro's ergonomic grip not only enhances control but also reduces hand fatigue during prolonged sessions, making it a favorite among automotive technicians tackling fleet maintenance. Its compact designs, especially the 1/4" variant, fit easily into tight spaces, while the broader range of the 1/2" model handles larger fasteners with ease. Durability is another hallmark; the chrome-plated heads resist wear from constant use, ensuring the tool remains reliable season after season.

Digital Torque Wrenches: When Technology Meets Torque

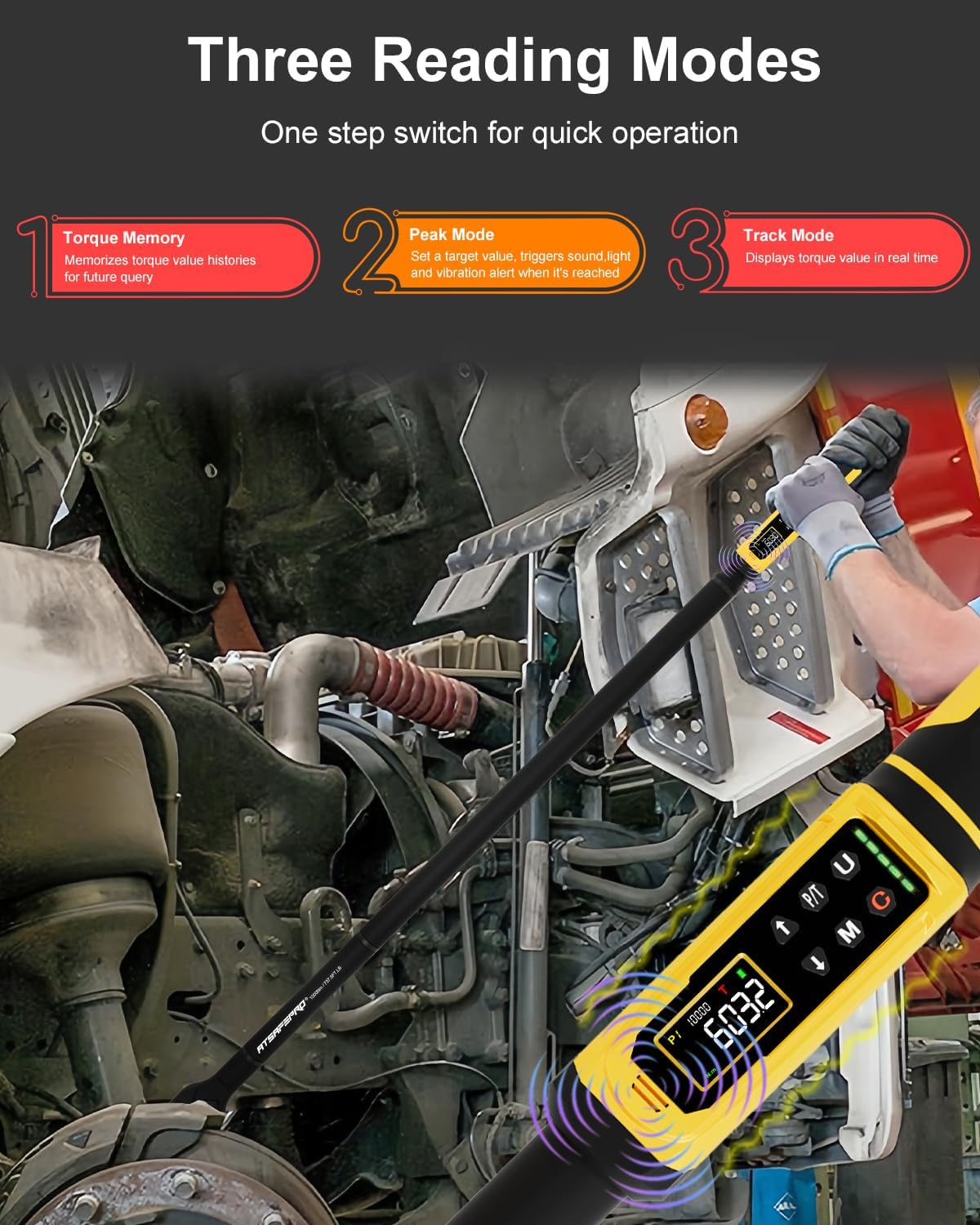

For users exploring beyond traditional tools, a Digital Torque wrench introduces innovative features that complement the ATSafePro lineup. These devices often include data logging capabilities, allowing you to track torque applications for compliance in regulated industries. Peak hold functions capture the maximum torque applied, providing detailed records that mechanical wrenches can't match without additional accessories. Yet, integrating a Digital Torque wrench with the ATSafePro's mechanical precision can create a hybrid approach: use the digital for verification in critical tasks and the mechanical for everyday reliability. The ATSafePro Torque wrench's locking feature mirrors the set-and-forget convenience of digital presets, but without the vulnerability to electronic glitches in dusty or oily workshops.

Practical Applications and Tips for ATSafePro Users

In practical scenarios, the ATSafePro Torque wrench shines across diverse applications. Automotive enthusiasts rely on the 3/8" model for wheel lug nuts, ensuring even tightening to prevent warping or loosening over time. In construction, the 1/2" version secures structural bolts with pinpoint accuracy, contributing to safer builds. For hobbyists restoring vintage machinery, the 1/4" wrench's inch-pound range handles sensitive components without over-torquing. To maximize performance, always calibrate your ATSafePro Torque wrench periodically, store it in a dry environment to protect the scales, and pair it with quality sockets for optimal results. Whether opting for a mechanical torque wrench or considering a digital upgrade, the ATSafePro series provides a foundation of excellence that adapts to your needs.

Why Choose ATSafePro for Your Torque Needs

Ultimately, the ATSafePro Torque wrench represents a commitment to quality and innovation in torque tools. Its blend of mechanical reliability and user-friendly design makes it indispensable for professionals demanding precision without complexity. By choosing ATSafePro, you're investing in tools that endure, perform, and elevate your work. Whether navigating the tactile assurance of a mechanical torque wrench or the tech-forward appeal of digital options, this series ensures you're equipped for success in any mechanical challenge.