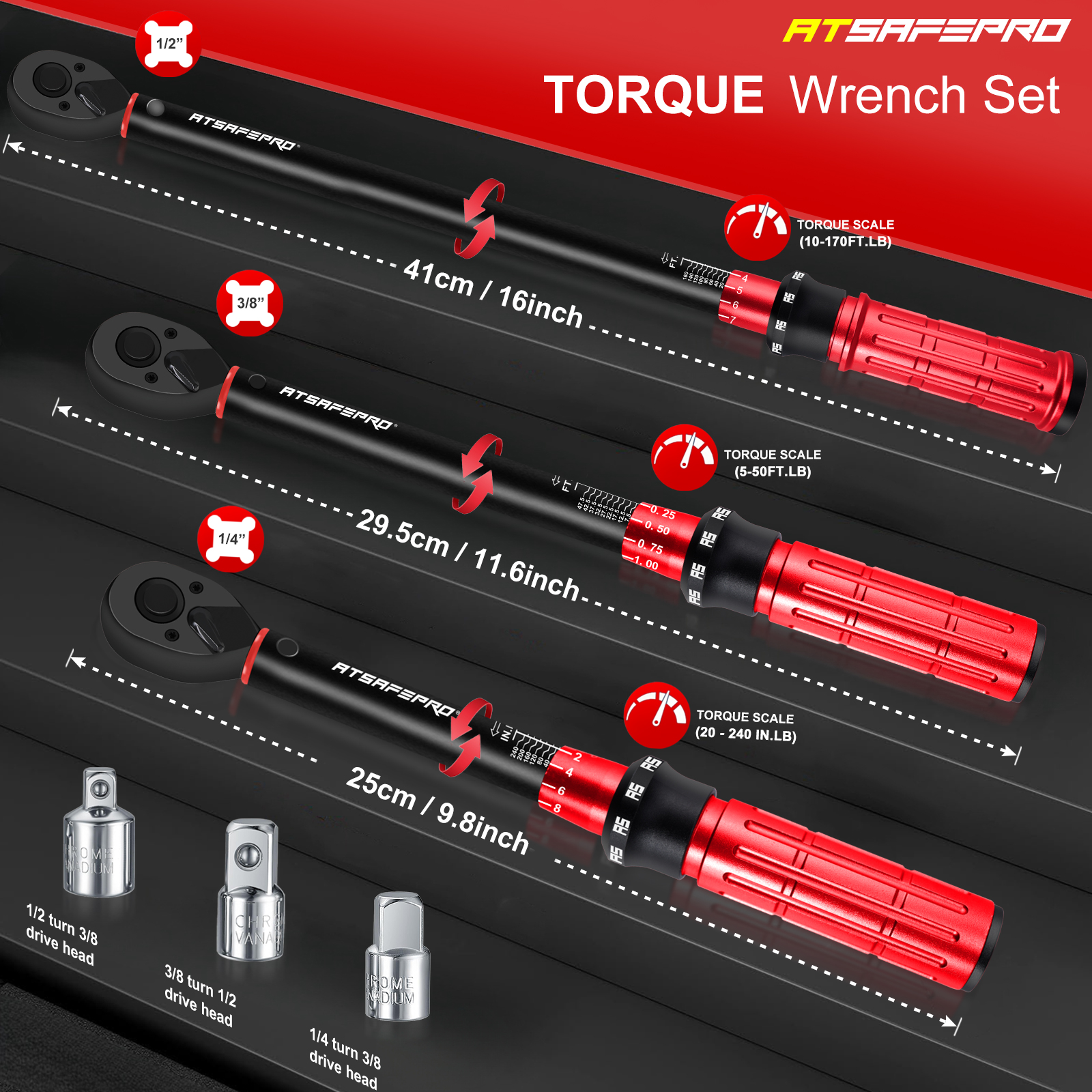

Torque Wrench Maintenance Tips: Keep Accuracy for Years of Reliable Use

Precision Tools Fail Without Proper Care

Unlike common wrenches, a Torque Wrench is designed to deliver exact force in Newton-meters or foot-pounds. Even a deviation of 10% can strip threads on spark plugs or leave wheel lugs dangerously loose. Studies from SAE International show that improper fastener tightening contributes to up to 20% of mechanical failures in vehicles. This highlights why maintaining calibration and proper handling is essential—not just for tool longevity, but for safety.

The Pain Points Mechanics Often Face

Real-world users frequently report recurring problems when torque wrenches are poorly maintained:

-

Unexpected Inaccuracy: A digital screen shows numbers, but the tool has drifted out of calibration.

-

Premature Wear: Dirt inside the ratchet head causes skipped clicks and uneven torque delivery.

-

Spring Fatigue: Forgetting to reset a mechanical wrench leaves the spring compressed, weakening accuracy.

-

Storage Damage: Tools stored in humid garages develop rust and corrosion.

Solution: Treat torque wrenches like measuring instruments, not heavy-duty levers. Regular cleaning, annual calibration, and controlled storage environments eliminate these risks.

Daily Care Habits That Protect Accuracy

Building habits after each use keeps a torque wrench reliable for years:

-

Reset to Zero – Always set a Mechanical Torque Wrench to its lowest scale after use to release spring tension.

-

Wipe and Protect – Clean surfaces with a lint-free cloth; avoid solvents near seals or electronics on Digital Torque Wrenches.

-

Never Use as a Breaker Bar – Loosening bolts with a torque wrench damages internal gears.

-

Case Storage Only – Keep tools flat in their case, away from sunlight and damp air.

Tip: For Digital Torque Adapters, remove the batteries if the tool will sit unused for months to prevent leakage damage.

Calibration: Your Annual Insurance Against Failure

Calibration restores a wrench to factory accuracy. Industry guidelines (per ISO 6789) recommend recalibration every 12 months, or sooner for heavy use.

| Torque Tool Type | Calibration Interval | Accuracy Risk if Ignored |

|---|---|---|

| Mechanical Torque Wrench | 12 months / 5,000 uses | Spring drift ±10% |

| Digital Torque Wrench | 12 months / 3,000 uses | Sensor misread ±5–7% |

| Digital Torque Adapter | 12–18 months | Circuit drift ±5% |

Many DIY mechanics only notice calibration issues after damage has already occurred (e.g., stripped oil drain plugs).

Solution: Keep a record of calibration dates, and send the tool for professional service before issues arise.

Storage and Environmental Factors Few DIYers Consider

How you store your wrench matters as much as how you use it:

-

Temperature: Ideal range is 10–30°C; heat can alter sensor performance.

-

Humidity: High moisture levels accelerate rust in Mechanical Torque Wrenches.

-

Shock Protection: Dropping a Digital Torque Wrench may knock sensors out of alignment.

-

Transport: For mobile mechanics, foam-lined cases reduce impact during travel.

Quick Comparison

| Environment | Risk | Recommended Practice |

|---|---|---|

| Damp basement | Rust and corrosion | Store in dry cabinet |

| Hot car trunk | Sensor drift | Keep below 30°C |

| Open toolbox | Dust contamination | Use case after every job |

Expert Tips for Long-Term Reliability

To extend both accuracy and lifespan, follow these pro-level habits:

-

Warm-Up Before Precision Work: On click-type wrenches, make 2–3 trial pulls at moderate torque to stabilize the spring.

-

Document Torque Jobs: For workshops, keep a log of critical torque settings applied—helps track consistency.

-

Use Anti-Seize on Spark Plugs: Reduces friction, ensuring torque readings reflect clamping force instead of thread resistance.

-

Pair with Short Extensions: Long bars distort torque delivery; shorter accessories maintain accuracy.

Q&A: Common User Concerns

Q: How do I know if my wrench is out of calibration?

A: If bolts feel loose despite correct settings, or if you’ve dropped the wrench, recalibration is likely needed.

Q: Can I calibrate a torque wrench at home?

A: Basic checks with a weight-and-lever method are possible, but professional labs ensure ISO-level accuracy.

Q: Does storage orientation matter?

A: Yes. Horizontal storage in a case prevents uneven internal wear over time.

Maintenance Is an Investment in Safety

A torque wrench is not just another garage tool—it’s a precision instrument that protects engines, wheels, and brake systems from costly mistakes. Skipping maintenance shortens tool life and compromises vehicle safety, but adopting proper habits—resetting, cleaning, calibrating, and storing correctly—ensures years of reliable use.

Explore the full range of ATSAFEPRO torque solutions on our homepage or get expert advice via our contact page.