Sustainability in Simplicity: Mechanical Tire Inflators as Long-Lasting Tools for Auto Service Chains

Service Chains Demand Reliability Over Complexity

Large auto service chains face one critical challenge: ensuring consistency across dozens or even hundreds of branches. Every tool used—from lifts to diagnostic devices—affects efficiency, cost, and reputation. While digital tools attract attention for their modern features, many chains still rely heavily on the Mechanical Tire Inflator With Gauge because it offers something digital models can’t: dependable accuracy without the risks of battery failure, software glitches, or frequent recalibration.

According to a Tire Industry Association (TIA) report, more than 40% of tire-related service delays come from equipment downtime. Mechanical inflators, with their simplicity, directly reduce these risks.

Why Mechanical Inflators Drive Sustainable Operations

In professional environments, “sustainability” means more than eco-friendly slogans—it translates into reducing waste, prolonging tool life, and cutting avoidable costs. Mechanical inflators achieve this by combining simple engineering with long-term resilience.

-

Built to Last: Heavy-duty casings, brass components, and reinforced hoses withstand daily use in busy workshops.

-

Low Upkeep, High Returns: Unlike digital inflators, they require no software updates or battery disposal.

-

Consistency Across Locations: Auto service chains benefit from standardized tools that deliver uniform results, simplifying training and audits.

-

Eco-Friendly Lifecycle: By avoiding electronic waste and reducing tool replacement frequency, they align with corporate sustainability goals.

Mechanical vs. Digital: What Service Chains Should Consider

| Feature | Mechanical Tire Inflator With Gauge | Digital Tire Inflator With Gauge |

|---|---|---|

| Accuracy | ±1 PSI, reliable in heavy use | ±0.5 PSI, requires recalibration |

| Power Needs | None | Battery or electricity |

| Durability | Resistant to dust, oil, and shock | Sensitive to moisture and electronics |

| Maintenance | Occasional check | Regular calibration and updates |

| Environmental Impact | No e-waste | Battery disposal required |

| Ideal Buyer | Auto service chains, fleets, OEM buyers | Data-driven fleet managers |

This comparison highlights why service chains and fleets prioritize reliability over advanced features when scaling operations.

Real-World Applications in Auto Service Chains

-

High-Volume Workshops: Chains handling 50+ vehicles per day benefit from tools that don’t interrupt workflows with charging or recalibration.

-

Fleet Maintenance Centers: Logistics hubs where trucks rotate daily depend on durable equipment to minimize costly roadside tire failures.

-

Emerging Markets and Harsh Conditions: In regions with unreliable electricity or high humidity, mechanical inflators outperform digital counterparts due to their resilience.

-

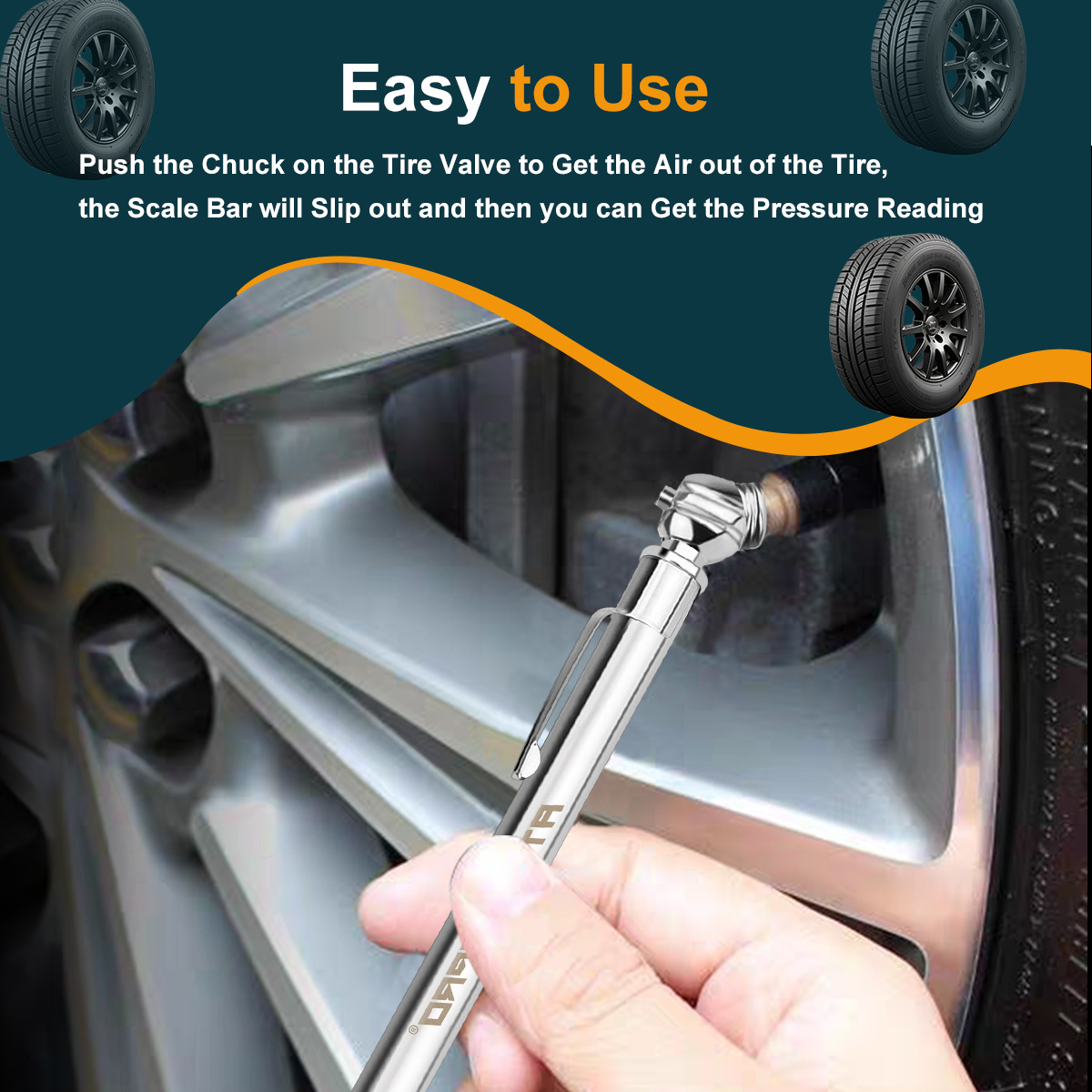

Training for New Technicians: Simpler design reduces the learning curve, ensuring entry-level staff achieve accuracy from day one.

Buyer-Oriented Q&A

Q: Are mechanical inflators still accurate enough for modern tire standards?

A: Yes. ATSAFEPRO models maintain accuracy within ±1 PSI, which meets global automotive requirements and ensures safe operation across vehicles.

Q: How do they contribute to cost savings for service chains?

A: By reducing calibration downtime, eliminating battery replacements, and extending service life, they lower operating costs significantly over time.

Q: What about large fleets?

A: Fleets benefit from standardized tools, ensuring consistent tire pressure management across hundreds of vehicles without introducing digital maintenance complexity.

ATSAFEPRO’s Advantage in Mechanical Tire Tools

ATSAFEPRO’s Mechanical Tire Inflators With Gauges are engineered for service chains that demand reliability and long-term value. Our tools combine rugged materials, ergonomic design, and proven precision, making them suitable for both local repair shops and international automotive networks.

By aligning with the priorities of fleet managers, workshop owners, and chain operators, ATSAFEPRO ensures every inflation meets industry standards without unnecessary complications.

Long-Term Value for Professional Tire Care

In auto service chains, the simplest tools often deliver the greatest sustainability. A Mechanical Tire Inflator With Gauge is not just a cost-saving choice—it’s a long-term investment that strengthens reliability, reduces waste, and supports business growth.

Explore ATSAFEPRO’s full tire tool solutions on the homepage or get in touch via the contact page for tailored advice.